Packaging Life Cycle Analysis: What It Tells Us, What It Doesn’t, And How We Use Them

Posted By on Jan 18th 2024

Packaging Life Cycle Analysis

Life cycle analyses and emissions assessments are increasingly used by brands to help them make eco-conscious choices when designing products, packaging, and making operational decisions. This analysis is a significant step forward.

However, it is crucial to recognize that LCAs are not a perfect science - results will vary (often drastically) across different tools, and only some LCA software solutions give insight into the assumptions driving their calculations.

Additionally, LCAs often provide outputs that counter other goals, such as plastic reduction and curbside recyclability. This post (1) delves into these complexities to help your brand factor in results thoughtfully and (2) outlines the LCA tools EcoEnclose typically uses for different materials and why we have made that choice.

What is a Life Cycle Analysis (LCA)?

As we all know, comparing the environmental implications of different choices is very complex.

Is it better to eat an organic tomato from Spain or a non-organic tomato grown in your state? Is it better to use recycled plastic manufactured in California or virgin paper manufactured in China? Is buying used furniture or certified, sustainably sourced wood furniture better?

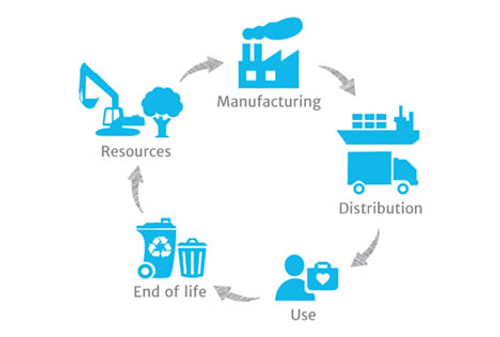

A life cycle analysis aims to answer these questions more quantitatively and systematically. Sphera, one of the two software solutions EcoEnclose uses for our own LCA analysis, defines an LCA as the systematic analysis of the potential environmental impacts of products or services during their entire life cycle.

When running an LCA, the user inputs various data, including the weight of material, the type of material used, recycled content included, manufacturing processes used, location of manufacture, shipping distances, and end-of-life scenarios. The software, using proprietary algorithms and assumptions, will provide different outputs to help the user compare and decide between options. Different LCA software will give different outputs, but most will provide data such as:

- Carbon emissions

- Fossil fuel requirements

- Water usage

- Eutrophication

While LCA software typically does not claim that one point of output is more important than others, most users of an LCA prioritize carbon emissions above others, given that carbon emissions are the primary driver of climate change, the most pressing environmental issue facing the planet today.

The Difference Between Preliminary Versus In-Depth LCAs

We consider a preliminary LCA to allow users to input their information and then use broad industry data to provide reasonably quick results. The more detailed the data a user has, the more accurate and relevant the output will be.

An in-depth LCA would be one in which a user gathers significant detail on their materials, products, and supply chain, including specific information on where raw materials are sourced, what kind of energy is being used to fuel manufacturing and transport across the supply chain, accurate data on the end of life trends for the product and packaging, etc. Expert consultancies typically conduct these in-depth LCAs, costing tens of thousands of dollars to execute.

A preliminary LCA is a great starting point for discussion and decision-making, and we’ve found that the directional output they put forth is fairly close to the final data outputted by a more in-depth LCA. However, these preliminary LCAs should never be used to provide a concrete public data point about the carbon footprint of a product or packaging solution. Nor should they be used to calculate a company’s carbon emissions for offsetting or accounting.

LCA Tools and Calculators EcoEnclose Utilizes

EcoEnclose uses several different approaches and tools to produce preliminary calculations of our packaging solutions' environmental impact and savings to help our EcoAllies make more informed decisions about their optimal packaging strategy.

Trayak and Sphera: Paid software solutions allow us to conduct preliminary LCAs on various materials, including paper, LDPE, PET, bio-plastics, some fabrics, and more.

Environmental Paper Network: Because software systems like Trayak and Sphera consider the logging of trees a carbon-neutral activity, we generally leverage the Environmental Paper Network’s LCA to derive calculations related to paper-based packaging. This LCA publishes all its calculations and assumptions, which you can read in full here. Our Eco Savings calculators for paper products and corrugated boxes are directly connected to the EPN’s tool and assumptions.

EPA, Stanford, Centre for Environmental Sciences Data, Argonne National Laboratory: Because Trayak and Sphera do not make their assumptions public, and because of some of the unexplainable results we see at times when reviewing their output, we have also established a simple preliminary calculator for our polyethylene products. This calculator leverages public data sources - including the EPA, Stanford, Centre for Environmental Sciences Data, and the Argonne National Laboratory - that have assessed the average carbon, oil, and energy footprint of a set volume of polyethylene.

The basic assumptions fueling our simple calculator are as follows.

|

|

UNITS | Virgin | 100% RECYCLED |

| Material | LDPE | Virgin LDPE | 100% Recycled LDPE |

| Weight | Pounds | 1000 | 1000 |

| Recycled Content | Percentage | 0 | 100% |

| Feedstock Used | Barrels of Oil (Eq) | 4.5 | 0 |

| GHG Emissions | Lbs CO Eq | 4838.3 | 2883.3 |

| Total Energy | Million BTUs | 94.8 | 45.8 |

Sources: Greenhouse gas emission factors for recycling of source-segregated waste materials, The Link Between Plastic Use and Climate Change: Nitty-gritty, Life cycle greenhouse gas emissions and energy use of polylactic acid, bio-derived polyethylene, and fossil-derived polyethylene

We fully recognize that the resource requirements and emissions associated with the production of virgin and recycled LDPE vary drastically based on where and how the source inputs (fossil fuels) are extracted, the local versus global nature of the recycling supply chain (for the 100% recycled alternatives), the sources of energy fueling manufacturing, and so much more. Our assumptions serve as an average baseline and a starting point for decision-making. We continue to evolve them based on the most up-to-date and vetted data available.

Limitations of LCAs and Environmental Calculators

While an LCA is an excellent tool that should be used alongside others when making packaging and product development decisions, there are important limitations to consider.

Here is just a sampling of these limitations. EcoEnclose sometimes considers these limitations, so we choose one specific LCA approach over another. In other situations, we simply recognize and are transparent about the limitation while still using the tool’s LCA results and may decide to factor the results differently into our decisions.

System Boundaries: While an LCA is a life cycle analysis, the analysis has to assume the cycle's beginning and endpoints. These are system boundaries that determine which unit processes to include in the LCA study. Defining system boundaries is a bit of a subjective choice, though software and services tend to make similar assumptions on the boundaries, called “cut-off points.” A life cycle often begins at the extraction point of raw materials and concludes with the end of life, including energy generation, if relevant. There are also time limitations, such as the lifespan of the impacts of pollutants generated, etc. These cutoff points are necessary components of an LCA but can also hide major drivers of the environmental impact of certain materials.

Biogenic Carbon: When assessing renewable inputs, the question of whether or not to account for biogenic carbon and how to account for biogenic carbon is hotly debated. Biogenic carbon is " derived from material of biological origin excluding material embedded in geological formations or transformed to fossilized material and excluding peat.” In layman’s terms, this means that when packaging is derived from something “readily renewable” (versus fossil fuels or minerals), biogenic carbon accounting would consider the carbon sequestered in that material as it grows that continues to be stored over its lifetime. If we are talking about sugarcane, for example, biogenic carbon absorbed by the sugarcane would be assessed by a factor of -1 (a unit of reduction in carbon emissions through sequestration). If the material then burns or decays, some or all stored carbon is released into the atmosphere and must be characterized with a factor of +1 (i.e., a unit released of those carbon emissions).

Whether or not to include biogenic carbon is not necessarily agreed upon. Unfortunately, many assessments omit carbon losses from logging in primary forests, resulting in only a partial picture of climate impacts (EPN).

Additionally, some systems, such as Sphera, now show results with and without biogenic carbon accounting, leaving the user to decide which approach to adopt.

Assumptions and Algorithms: LCA software is driven by complex algorithms and many assumptions. One of the most challenging aspects of LCA software is that the user has very little insight into the formulas and data driving the results unless we push and request specifics.

One example of an assumption is the Global Warming Potential for different types of greenhouse gasses. 100-year GWP is the standard - representing the energy absorbed by a greenhouse gas over 100 years. Recently, policymakers and scientists have recognized the importance of considering the 20-year GWP, which represents the energy absorbed by a greenhouse gas over 20 years. Methane, a greenhouse gas with a much more significant negative impact than CO2 but over a shorter lifetime, has a 100-year GWP of 27–30, compared to its 20-year GWP of 81–83. The Environmental Paper Network calculator is driven by 100-year GWP for gasses with a longer lifetime (CO2) and 20-year GWP for gasses with a shorter lifetime (methane), an approach that many scientists now believe puts forth data that better reflects and reinforces the short-term urgency of reversing climate change.

Few LCA tools will give the user precise information on 100-year versus 20-year GWP and why a given assumption is being used.

Paper calculation discrepancies highlight a myriad of other undisclosed assumptions.

For example, we recently conducted analyses to understand the carbon footprint of virgin paperboard versus recycled paperboard. We found that in Trayak and Sphera, virgin paper is assumed to have a lower carbon footprint than recycled. The surprising results led us down a long path of inquiry with both teams, leading to some helpful insights into their assumptions.

Trayak shared that there isn’t always enough data on many recycled paper substrates. When insufficient data is available, the algorithm uses default assumptions based on “industry average paper, woodfree, uncoated.”

Anytime a default assumption is used for a recycled paper type, the output isn’t accurate.

Sphera also shared that they assume that logging is a carbon-neutral activity, seeing every tree as one that will be replanted - an assumption that is not one the broader environmental and scientific community agrees on.

Additionally, recycled paper requires external fossil energy, causing upstream CO2 emissions.

Sphera recognizes that the virgin paper production process is energy-intensive, but the energy is – in modern plants - produced by incinerating the waste wood on-site. So, modern integrated paper plants produce their energy and export surplus energy. Since the energy is derived from what Sphera considers a “carbon neutral effort” (logging trees), virgin paper is rewarded because wood chips are used as an energy source.

These are all assumptions we take major issue with as they do not reflect the actual state of the logging and pulping industry and problematic trends related to deforestation.

A fantastic article by the Environmental Paper Network provides excellent commentary on this: “Currently, many LCAs commissioned by industry sources are not considering the entire scope of climate impacts, including short-lived climate pollutants, like emissions of black carbon, which are the second highest contributor to climate change after carbon dioxide emissions. In addition…many recent LCAs do not consider stored carbon that is lost during timber harvest, assume that all forestry is “carbon neutral,” and create carbon accounting scenarios that assume the forest will be replanted….Hundreds of scientists have stated that it is not accurate or based in science to assume that burning wood for energy has no effect at all on the climate. In order to effectively reduce our emissions, we must first account for them accurately.”

Whether or not a user believes the assumptions made by Sphera and Trayak are valid, we think it is a severe limitation of LCA software that these details aren’t made clear to users when data is first outputted.

Because of this lack of transparency and the decision to assume that logging is a carbon-neutral activity, we have chosen to leverage the Environmental Paper Network for our paper-based packaging calculations. Their assumptions are 100% available to all users.

Not factoring in some critical environmental issues: The analytical focus of an LCA and the system boundaries that are in place means that critical issues aren’t factored in. For example, when considering renewable inputs into materials such as wood, bagasse, corn, or sugarcane, the analysis does not factor in the impact of land use conversion and the resulting impact of land conversion on carbon emissions and biodiversity loss.

This can be a significant oversight for specific inputs, such as conventionally produced corn or sugarcane, as converting rainforest and natural prairie land into farmland has dramatically impacted carbon emissions and biodiversity loss.

Additionally, an LCA doesn’t take into account litter and pollution issues.

Though plastic pollution is a critical issue facing the planet today, there is no powerful way to quantify this within an LCA.

The output is never the same across the two systems: For us, what was surprising was to see how much results often varied between Sphera and Trayak. Many people we speak with think an LCA is rock-solid science and that the resulting output can be considered fact. When we first started seeing these drastically different results across the systems, it surprised us. But it also led us to dig in on the ins and outs of how these algorithms work. Hopefully, the above insights will help dispel the misconception that LCAs should be considered gospel.

How These Limitations and Variations Show Up in LCA Results

This section outlines results we’ve seen in some of our own LCA analyses across different systems. These results are informative, often as the starting point for more in-depth research and investigation. Some of these results provide concrete support to our decision-making.

Plastic Almost Always Beats Paper When Measuring Carbon Emissions

Many people who use an LCA are looking to compare paper versus plastic.

Plastic film will almost always win in an LCA because plastic packaging uses significantly less material to accomplish the same functionality as a paper counterpart.

The following analysis compares 1000 6x9 100% recycled poly mailers with 1000 6.5x8.75” 100% recycled paper mailers. These results were generated through Sphera, but similar trends are found in Trayak's analysis.

While the results aren’t necessarily surprising for most people passionate about sustainability and packaging, they do serve as a sometimes frustrating reminder of how a prioritized focus on carbon emissions can lead to packaging decisions that don’t necessarily address other vital issues - such as our reliance on fossil fuels, adverse health consequences associated with widespread plastic use, and the importance of mitigating ocean plastic pollution.

Trayak and Sphera Show that Recycled Paper Has a Higher Carbon Footprint Than Virgin Options. EPN’s Calculator Does Not.

The following shows the difference between 1 lb of 100% post-consumer paperboard and 1 lb of virgin paperboard, using Trayak as an LCA tool.

As described above, many LCAs, including Trayak and Sphera, consider logging carbon neutral and then credit virgin paper pulpers for converting wood chips from logged trees as their energy source - and selling this energy.

In contrast, the following shows results from the Environmental Paper Network calculator, a tool that fully accounts for the biogenic carbon loss related to logging.

WTE and Composting Paper Has a Higher Carbon Footprint Than Landfilling

The following compares 1 lb of recycled paper mailers versus landfilled versus converted to energy.

Interestingly, landfilling the paper has a lower carbon footprint than energy conversion or composting.

The composting of biomaterials like paper leads to a portion of that material’s carbon being emitted back into the atmosphere (some carbon is absorbed in soils).

On the other hand, when materials like paper are landfilled, they decompose very slowly. While that slow decomposition does result in landfill gas emissions, results from LCAs like Trayak and Sphera suggest that these emissions are significantly below that of composting.

These results were from Trayak.

Factoring in Biogenic Carbon Can Have a Major Impact

The following table shows results from Sphera comparing 100 lbs of bio-based HDPE (derived from corn) versus 100 lbs of virgin, petro-based HDPE. The first row compares emissions without factoring in biogenic carbon, while the second row includes biogenic carbon loss.

|

|

HDPE (Corn) | HDPE (virgin, fossil fuels) |

| Climate Change [kg CO2 eq.] | 3.388 | 3.087 |

| Biogenic GHG emissions [kg CO2 eq.] | 351.743 | 0.049 |

| Emissions from land use change (dLUC) [kg CO2 eq.] | 0.013 | 0.000 |

| Water use [m³ world equiv.] | 17.637 | 0.540 |

| Primary energy demand, non-renewable [MJ] | 48.547 | 85.779 |

| Primary energy demand, renewable [MJ] | 87.497 | 3.497 |

| Primary energy demand, total [MJ] | 136.045 | 89.276 |

| Acidification [kg SO2 eq.] | 0.034 | 0.004 |

| Smog Air [kg O3 eq.] | 0.324 | 0.107 |

| Blue water consumption [kg] | 517.135 | 15.826 |

The following table shows results from Sphera comparing 1000 lbs of virgin paper versus 1000 lbs of 100% recycled paper. The first row compares emissions without factoring in biogenic carbon, while the second row includes biogenic carbon loss.

| 1000 lbs of virgin paper | 1000 lbs of recycled paper | |

| Climate Change [kg CO2 eq.] | 0.606 | 0.898 |

| Biogenic GHG emissions [kg CO2 eq.] | 3.492 | 1.566 |

| Water use [m³ world equiv.] | 0.107 | 0.117 |

| Primary energy demand, non-renewable [MJ] | 5.003 | 8.275 |

| Primary energy demand, renewable [MJ] | 37.036 | 1.895 |

| Primary energy demand, total [MJ] | 42.039 | 10.170 |

| Acidification [kg SO2 eq.] | 0.003 | 0.001 |

| Eutrophication [kg N eq.] | 0.001 | 0.001 |

| Particulate Air [kg PM2.5 eq.] | 0.000 | 0.000 |

| Smog Air [kg O3 eq.] | 0.062 | 0.023 |

| Blue water consumption [kg] | 2.130 | 9.085 |

For bio-based materials, the impact of biogenic carbon can be tremendous, and how to best factor it into decision making is driven by several factors.

Compostable PLA Bioplastic Loses

The following is a high-level analysis comparing 10 lbs of recycled LDPE versus 10 lbs of virgin LDPE versus 10 lbs of PLA. This analysis assumes that film extrusion was the manufacturing method applied. With recycled LDPE outperforming all and PLA having a higher carbon footprint than virgin and recycled counterparts, these results were accurate across both systems and all plastic manufacturing processes. These results were from Trayak.

Landfilling Bioplastic Has a Lower Carbon Footprint than Composting

The following shows 10 lbs of PLA mailers that are composted versus landfilled. Interestingly, composting PLA has a higher carbon footprint than landfilling it. Again, this is because these tools account for the carbon emitted into the atmosphere when biomaterials compost. PLA decomposes significantly more slowly in landfills, resulting in much lower emissions. These results were from Trayak.

How Does EcoEnclose Use Life Cycle Analyses and Eco Calculations?

To celebrate our community’s impact and resources saved - using optimal tools for our materials - while also recognizing the limitations of these results.

We have developed Eco Savings calculators for our EcoAlly community. Our calculator for paper-based packaging is built on top of the Environmental Paper Network Calculator. In contrast, our plastic-based packaging calculator is driven by simple assumptions derived from publicly available research and white papers.

We believe these Eco Savings calculators are a tremendous tool in helping our brands quantify the impact of their investments in recycled packaging and communicating the ecological value of these decisions to end consumers.

We do not, however, believe these results should be used as part of regulated carbon accounting practices. They intend to be broad and agnostic to many of the specifics related to an individual brand’s operations - such as where exactly packaging is being shipped and how customers dispose of a brand’s specific packaging.

As described above, different companies have unique requirements for structuring LCAs. For example, GHG Protocols require methane emissions to be driven by a 100-year Global Warming Potential horizon. The Environmental Paper Calculator has opted for a 20-year GWP horizon for methane due to the shorter life of this greenhouse gas.

For EcoAllies who pursue in-depth carbon accounting across their operation, leveraging their software or third-party consultants to support these efforts, EcoEnclose can share comprehensive data needed to quantify the environmental impact of your packaging with us. This data will include total quantity, packaging weight, material type, recycled content (including post-consumer and post-industrial waste), state/country of manufacture, life trends, and more.

To serve as a valuable starting point for decision-making and research.

We believe preliminary Life Cycle Analysis, such as one done through self-directed software like the Environmental Paper Network Calculator, Trayak, and Sphera, should be considered as one initial data point in evaluating packaging decisions, but not the decision factor. One of our favorite ways to use an LCA is to create a baseline from which to ask questions and identify where we want to research further.

For example, we were recently evaluating the merits of sugarcane-based, recyclable bioplastic. The life cycle analysis output suggested that this type of plastic has a very low and, in some cases, negative carbon footprint. However, the LCA also showed this to have an extremely high negative impact on eutrophication, producing excessive richness of nutrients in a lake or other body of water that creates destructive algal blooms. This disconnect led us to research the sugarcane production process more thoroughly to understand better this crop's pros and cons on carbon, land use, ocean, and the planet’s long-term health.

It has helped us recognize that if and when we pursue sugarcane-based materials, we must seek out sustainably grown crops whose production processes have minimal harm to the ocean, as well as land use conversion and deforestation.

To supplement, but not replace a well-developed sustainability vision and framework.

At EcoEnclose, our primary vision is to create a packaging future that is circular and regenerative. We imagine a day when goods are endlessly recycled or reused and that any virgin materials are made from regenerative resources whose production strengthens soils, waterways, habitats, air quality, and local communities.

With this as our north star, we have heavily prioritized recycled content. Through this lens, we use an LCA to help us get smarter and make thoughtful decisions within the boundaries of circularity, but we don’t allow LCA results to push us to forego our vision.

For example, an LCA would tell us that a virgin, landfilled poly mailer made overseas has a lower carbon footprint than a 100% recycled paper mailer made in the USA. We don’t let these results, which do not recognize the pitfalls of a linear economy or the massive plastic pollution problem, derail us from our vision. But we use the results to help us get more thoughtful about creating a circular, regenerative, carbon-efficient, and even carbon-negative future.