What Are Eco-Friendly Mailers? Types, Materials, and Recyclability

Posted By on Nov 7th 2025

What Are Eco-Friendly Mailers?

Types, Materials, and Recyclability

Sustainability has never been more important. Recent trends in sustainable shopping indicate that most consumers expect brands to adopt environmentally responsible practices, and businesses that fail to do so risk losing customer trust and revenue. For eCommerce companies, packaging is one of the most visible and effective ways to demonstrate that commitment.

If you’re shipping apparel or other soft goods, you’re likely using poly mailers to package your orders. But with so many options—recycled, compostable, and biodegradable—it can be difficult to know which ones are truly sustainable. And if most of them are still made from plastic, can any really be considered eco-friendly?

That’s what this guide is for. We’ll explain what makes eco-friendly poly mailers sustainable, outline the trade-offs to weigh, and help you choose the right option for your brand.

Key Takeaways

-

Eco-friendly mailers reduce environmental impact by using recycled and recyclable materials designed for circularity.

-

Recycled poly mailers made with high post-consumer content minimize virgin plastic use and close the recycling loop.

-

Reusable designs, like dual-seal strips, cut waste and extend each mailer’s lifespan.

-

Avoid “biodegradable” claims—these additives can create microplastics and methane emissions in landfills.

-

Recycling beats composting for most eCommerce packaging due to limited industrial compost infrastructure.

-

EcoEnclose poly mailers are 100% recycled (50% post-consumer), reusable, recyclable, and made in the USA with water-based inks.

Table of Contents

- What Are Eco-Friendly Mailers?

- How Do Sustainable Mailers Support Zero-Waste Packaging?

- Types of Eco-Friendly Poly Mailers

- Why Reusability Matters for Circularity

- What to Consider When It Comes to Sustainability

- Are Recycled Poly Mailers Strong Enough for eCommerce?

- FAQs About Eco-Friendly Mailers

- How EcoEnclose's Recycled Poly Mailers Stand Out

What Are Eco-Friendly Mailers?

Eco-friendly mailers are shipping bags designed to reduce environmental impact through their materials and end-of-life pathways. That means prioritizing recycled content, recyclability, and—in limited, infrastructure-supported cases—compostability. This way, you can ship securely while using fewer virgin resources and keeping materials in circulation.

Poly mailers—a specific type of mailer—are made from lightweight, durable, moisture-resistant plastic (polyethylene) film, typically LDPE. They're practical for shipping soft goods, but their environmental impact is significant. The goal isn’t to pretend plastic is harmless—it’s to choose the most eco-friendly options available.

Unfortunately, not all “eco” mailers live up to their claims. Greenwashing remains common, even as more consumers become savvy about sustainability. Choosing truly responsible packaging requires transparency, proof, and a commitment to continuous improvement.

At EcoEnclose, that commitment is guided by our Sustainable Packaging Framework

—a holistic approach that evaluates materials, recyclability, and circularity to ensure every design supports real environmental progress.

Grounded in this framework, EcoEnclose designs mailers that perform responsibly from production to reuse. Our environmentally friendly poly mailers are:

-

100% recycled and made with 50% post-consumer waste

-

Reusable with dual adhesive strips

-

Recyclable with thin film

-

Printed with water-based ink, which releases little to no VOCs into the environment

Order a free sample here to see and feel the difference between our mailers and everyone else’s.

Source: EcoEnclose

How Do Sustainable Mailers Support Zero-Waste Packaging?

Many poly mailers bill themselves as sustainable just because they are recyclable. To us, that is just table stakes. We and most other sustainability and packaging experts believe “truly sustainable” eCommerce packaging should be designed with circularity in mind.

This means 100% recycled inputs and maximum recycling rates, ideally with poly film being recycled back into itself. The table below compares the ecological benefits of different categories of poly mailers.

Important note on “biodegradable” additives: Avoid these. Considerable research must still be done to substantiate these claims, and these types of plastics can cause harm to soils and water. Some are actually designed to release methane emissions when landfilled.

Source: EcoEnclose

Types of Eco-Friendly Poly Mailers

Pursuing circularity sets the foundation for sustainable packaging—and that begins with choosing the right poly mailers for your business. Each type offers different benefits in terms of material source, recyclability, and end-of-life impact.

Let’s break down the primary mailer types and how they support a circular system.

Recycled Poly Mailers

Recycled poly mailers are polyethylene plastic film mailers made from recovered resin instead of virgin plastic. That recycled content typically comes from two sources: post-consumer (PCR) material—reclaimed after use, such as collected films—and post-industrial (PIR/PIW) material—factory scrap captured before it reaches consumers.

Understanding the difference between these two sources is essential when assessing recycled packaging. Our guide to post-consumer versus post-industrial recycled content explains why this distinction matters and how it impacts a mailer’s true sustainability.

You might see multiple products labeled “100% recycled” and think they are identical. Often, they are not. If you select just any option labeled as such, you may be falling short of your sustainability mission and goals.

To ensure you're getting genuine recycled poly mailers, look for:

-

High post-consumer content - Go for the highest PCR percentage possible. EcoEnclose mailers contain 50% PCR and 50% post-industrial waste.

-

Domestic manufacturing - Choose mailers produced close to where they'll be used, from manufacturing partners that are observed, vetted, and committed to sustainable operations.

-

Dual-seal strips - With U.S. apparel return rates averaging 20–25% and rising during the holidays, reusable dual-seal mailers are essential for both sustainability and a smooth customer experience.

-

Verified recycled content claims - Look for Recycled Claim Standard certification (e.g., RCS100 for fully recycled products) or transparent PCR/PIR documentation and spec sheets when certification isn't present. Avoid mailers with big, bold statements like "I'm a 100% recycled mailer" but are fully post-industrial waste or lack clear proof of recycled content.

EcoEnclose has the only poly mailers on the market composed of 100% recycled content, half of which is post-consumer waste. While other manufacturers claim that their products are 100% recycled, we have found that they almost always refer to post-industrial waste composed of scraps produced from the first run of poly mailers using virgin content.

On the other hand, our mailers are made with materials that have already been used and discarded. They’re also recyclable themselves. You can bring them to a local grocery store that accepts plastic bags or take advantage of our Take-Back Program.

Recyclable Poly Mailers

“Recyclable” simply means that the packaging can be recycled. It does not mean that it has been recycled. Recyclable mailers, therefore, may be manufactured using virgin materials. This is despite the fact that there’s plenty of post-consumer waste we can rescue and reuse.

So what counts as recyclable poly mailers? Those made with LDPE with no metallic layers, foils, or mixed materials, whether virgin or recycled, are considered as such and accepted in many thin-film collection programs (e.g., grocery/store drop-offs).

While it is very important that all of these poly mailers are properly recycled so they can be given a second life, it would be disingenuous to call a recyclable poly mailer sustainable, given that 100% recycled (50% post-consumer) options are available.

Whenever possible, choose recycled-content mailers to reduce virgin resin demand—and then recycle the mailer after use to keep film in circulation. If a specific use case requires virgin LDPE, ensure the mailer is recycle-compatible (no foil/mixes) and provide clear how-to-recycle guidance to customers.

Compostable Mailers

Compostable mailers are films made from biopolymers—most commonly polylactic acid (PLA), polybutylene adipate terephthalate (PBAT), or cornstarch blends. These materials are designed to break down in industrial composting conditions, not in landfills or natural environments.

This type of poly mailer is often confused with biodegradable poly mailers, which are a different story. Biodegradable bags might sound great in theory, but they’re worse for the planet than traditional poly mailers. They’re usually still made with polyethylene, composed of oil and natural gas, but then they’re treated with an additive that speeds up the degradation process. The resulting microplastics are not recyclable and generally end up in landfills, releasing dangerous methane emissions as they degrade.

By contrast, certified compostable shipping bags or mailers are designed for industrial composting systems. Here's what you need to know:

-

Water resistance - Compostable mailers are moisture-resistant but generally less water/tear-resistant than LDPE, so they work best for soft goods without sharp edges.

-

Breakdown timeline - Certified compostable films typically break down in 90–180 days in industrial composting facilities. Home composting systems vary significantly, are slower to decompose, and often degrade the quality of home compost.

-

Compostable versus recyclable - Compostable mailers aren't necessarily better than recyclable mailers in most eCommerce scenarios. Unless you have reliable access to industrial composting and real collection pathways, high-PCR, recycle-compatible LDPE (or paper, where it fits) is the more circular choice.

-

Recycling compatibility - Compostable mailers cannot be recycled as they contaminate film-recycling streams.

Bottom line: prioritize recycled, recyclable, and reusable mailers and pair them with clear end-of-life guidance.

Certified compostable mailers should only be considered when you can ensure proper industrial composting at the end of their useful life. Because access to industrial composting facilities varies widely across regions, and compostable packaging degrades the quality of compost, we highly recommend recycling over composting for packaging.

Why Reusability Matters for Circularity

The most sustainable package is one that’s used more than once. Reusing mailers before recycling them extends their lifespan, effectively halving their per-use carbon footprint while reducing material use and handling costs.

EcoEnclose provides a practical solution to achieve this goal. Our dual-seal poly mailers, featuring two adhesive strips, allow customers to open the bag with a tear strip and easily reseal it for a return or a second shipment. This functionality simplifies the return process, minimizes packaging waste, and clearly shows your brand's commitment to the principles of a circular economy.

What to Consider When It Comes to Sustainability

Our research-based sustainability framework allows us to pursue only the most eco-friendly solutions. This prioritizes:

-

Ensuring circularity

-

Avoiding composting in lieu of recycling

-

Lowering greenhouse gas emissions

-

Manufacturing locally

We recognize that not all businesses have the same philosophy regarding operating in an eco-friendly way. That’s why we offer two kinds of sustainable, high-quality mailers.

Businesses that want to reduce carbon emissions can opt for our 100% recycled poly mailers, while those who want plastic-free options can use our 100% recycled paper mailers.

On the fence? Check out our guide to plastic versus paper mailers.

Key Features to Evaluate When Choosing Mailers

If sustainable poly mailers are the best fit for your needs, compare them on material strength, adhesive performance, design, and reusability specs. Also, ask for proof of recycled content (e.g., RCS or clear spec sheets).

Get these right and you’ll reduce damages, returns, and total cost per order. Here are the most important features to evaluate:

-

Strength - Unlike corrugated shipping materials, there’s no “edge crush test” to measure the durability of poly mailers. Instead, you will have to consider the thickness of the mailer and the way it’s sealed. For maximum protection, look for products composed of multiple layers with a secure seal on all three sides and a strong adhesive on the top.

-

Tear strip - No matter what you’re shipping, you probably don’t want customers to mangle the packaging with a knife or box cutter to get to their items. With a precise tear strip, the bag can be easily opened.

-

Release liner - The release liner protects the adhesive until you’re ready to seal the mailer. If you have to peel thousands of them, you want this step to be as easy—and static-free—as possible.

-

Bottom reinforcement - While our environmentally friendly poly mailers don’t have gusseted bottoms, the additional reinforcement can be helpful when shipping bulky or heavy items, like shoe boxes or thick quilts.

-

Dual peel and seal - A dual peel and seal is a double adhesive, each strip protected by a release liner. You can use the top strip for sending products out. Customers who want to make returns can then use the bottom one to seal the bag again before sending it back.

-

Tamper-evident closure - Some poly mailers have such a weak adhesive that you can peel and reseal them without leaving a trace. Our adhesive is strong enough to make our bags tamper-evident. If someone attempts to unseal the bag en route, the recipient will be able to tell. This helps mitigate missing and damaged items.

-

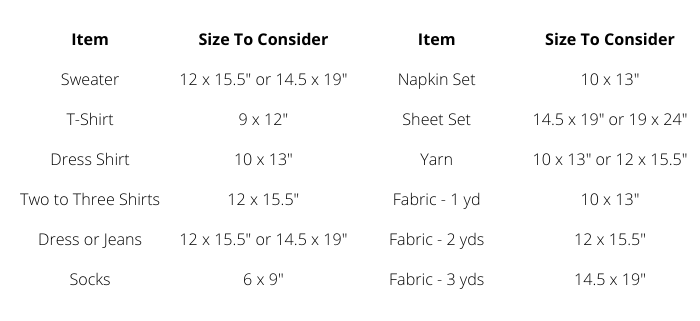

Size - You want your mailers to be large enough to fit your products easily but not so large that they have a lot of extra room or flimsy corners. The easiest way to choose the perfect size for every item is by ordering a host of samples and testing them individually. To help you get started, here’s a handy size chart with some generic dimensions.

Size Chart

Source: EcoEnclose

Are Recycled Poly Mailers Strong Enough for eCommerce?

Yes—when the spec is right, recycled LDPE performs on par with virgin LDPE for everyday eCommerce.

Performance Specifications

-

Durability - Multi-layer (co-extruded) recycled film at comparable gauge delivers similar tensile/tear performance to virgin film.

-

Seams & sealing - Heat-sealed side seams and a high-tack, irreversible self-seal provide closure strength comparable to virgin bags; failure modes are the same (improper seal, contaminated flap), not the resin source.

-

Tamper resistance - Tamper-evident adhesives behave similarly in recycled and virgin mailers—evidence of opening is a function of adhesive/liner system, not PCR content.

-

Moisture protection - Both recycled and virgin LDPE are moisture-resistant, not waterproof. For sharp, heavy, or liquid items, add inner protection (wrap/pad/box) to prevent punctures or leaks.

Value and Cost Efficiency

Not only are recycled poly mailers durable enough for eCommerce needs, but they're also a value-forward packaging choice.

-

Cost efficiency - Poly mailers are quickly becoming the most economical way to ship most physical goods. Since they’re cheaper to produce than corrugated cardboard, they can even give businesses enough wiggle room in their budget to customize their packaging supplies.

-

Dimensional & weight savings - Poly mailers are lighter and thinner than boxes, so they cost less to store, transport, and deliver. And if you get yours from EcoEnclose, you can save on returns, too. Customers who wish to return or exchange their products can send them back in the same mailer using the second adhesive strip to seal them.

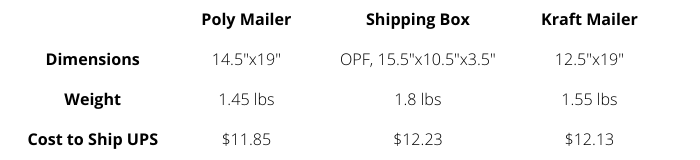

Using a concrete example, let's look at the potential savings. If you want to ship a men’s size large polar fleece from a warehouse in Louisville, CO (80027) to a customer in New York, NY (10007), here’s what you can expect to spend on each type of packaging:

That price difference might seem negligible when shipping a single item, but you can see how the savings quickly add up when you send out thousands—or hundreds of thousands—of products.

An added benefit of using poly mailers for especially lightweight items is worth noting. If your products are less than 13 ounces, you can use USPS First Class Mail, which starts at just $0.58 for one- to three-day shipping.

FAQs About Eco-Friendly Mailers

What are eco-friendly mailers made of?

Eco-friendly shipping mailers are commonly made from recycled materials—either recycled plastic film (LDPE) with high post-consumer content or recycled paper (kraft or paper-padded) that’s usually curbside-recyclable. Some are made from certified-compostable biopolymers (e.g., PLA/PBAT) intended for industrial composting only where that infrastructure exists. Quality options, such as those from EcoEnclose, also use water-based inks and recycle-compatible adhesives/ liners to keep the whole mailer recovery-friendly.

Can you reuse eco-friendly mailers?

Short answer: not all of them. “Eco-friendly” describes what something is made from and how it’s disposed of (recycled content, recyclable, or certified-compostable). Without a second seal (or resealable flap), clean-open tear strip, durable film, label space, and clear instructions, most recyclable or compostable mailers are still single-use. EcoEnclose favors circular design, prioritizing reuse features alongside recycle-compatible specs.

What happens at the end of a reusable poly mailer’s life?

Mailers with dual adhesive strips can be used twice. After their initial shipping, recipients can use them again to send back products or ship personal packages to others. Once poly mailers reach their second destination, they can be recycled at facilities that accept plastic bags and films. Encourage your customers to save their mailers alongside their grocery bags and make occasional drop-offs at the facility nearest them.

How are poly mailers recycled?

Depending on your curbside recycling program, they can be recycled residentially or at your local grocery store that accepts plastic bags.

We also are the only packaging company on the market offering a poly take-back program that allows your customers to stuff their EcoEnclose poly mailers with plastic film and ship them to our warehouse for recycling.

What can I ship with a poly mailer?

Poly mailers are the ideal shipping solution for fabric-based goods. Sometimes, they can also ship boxed items that need an outer layer, like shoes, prints, and stationary.

These types of mailers are not suitable for fragile items. If the products you ship could break en route, you probably want to use actual corrugated boxes with protective packaging and void fill. They are also unsuitable for sending several products in the same package.

For example, if you want to ship a t-shirt, wallet, and bottle of lotion, it’s probably better to use a box. Lumpy dimensions can make the mailers hard to scan en route, causing shipping delays.

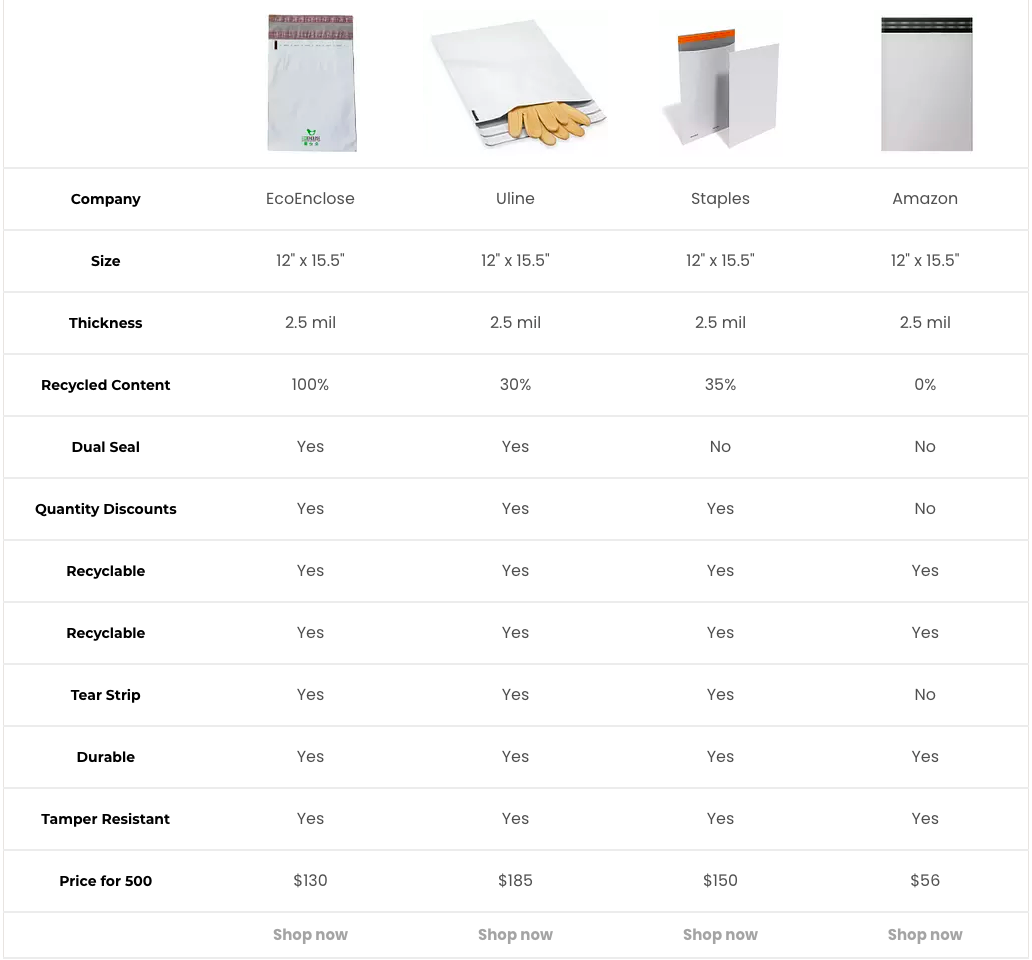

How much do eco-friendly poly mailers cost?

Poly mailers are like any consumer product; you get what you pay for. That doesn’t mean, however, that you must buy the most expensive ones on the market to ensure your products make it safely to their destinations.

The cost of each mailer depends on several factors, including size, durability, materials, reusability, and eco-friendly features. Here’s a chart with a rough comparison of similar mailers from four companies.

Cost Chart

When comparing prices, consider what your company stands for and what kind of impression you want to give customers. Durability also matters since items that are damaged en route will only cost you more in the long run. Put another way, getting a better quality shipping solution is often worth the extra 5 or 10 cents.

Where can I buy eco-friendly mailers in bulk?

You can buy eco-friendly mailers in bulk from sustainable packaging suppliers and wholesalers (look for high-PCR recycled film or recycled paper, credible certifications, and bulk-tier pricing).

If you want a one-stop, sustainability-first option, EcoEnclose offers bulk poly and paper mailers with the proof to match—100% recycled poly (50% post-consumer) that’s reusable (dual seals), recyclable, and printed with water-based inks, plus paper mailers made for curbside recycling. We also have an RCS100-certified poly-mailer line if you need third-party verification and a Plastic Film Take-Back Program to help close the loop.

How EcoEnclose's Recycled Poly Mailers Stand Out

If your goal is true circularity—not just a “recyclable” label—EcoEnclose builds for the full loop. Our standard recycled poly mailers use 100% recycled LDPE with 50% post-consumer content and include dual adhesive strips so each bag is reused before it’s recycled. They’re printed with water-based inks, made in the USA with vetted partners, and eligible for Take-Back Programs to keep plastic film in circulation rather than downcycled or landfilled.

For brands that need third-party verification, our RCS100-certified line confirms 100% recycled content (with ~56% post-consumer)—clear proof of what’s in the bag and why it belongs in thin-film recycling streams.

This is circular design in practice: high-PCR inputs, built-in reusability, and film-to-film recovery pathways—not downcycling that leaks material value over time. And because we’re family-owned, we pair that design philosophy with radical transparency (open specs, clear PCR/PIR splits, and certification detail) so you can confidently tell your sustainability story.

→ Explore EcoEnclose’s eco-friendly mailers—designed for durability, reusability, and circularity. Contact us for sustainable packaging support today.

About EcoEnclose

EcoEnclose helps forward-thinking brands deliver on their sustainability goals with innovative, research-driven packaging solutions designed for circularity.