Posted By on Aug 26th 2024

Sustainable Alternatives to Clear Poly Bags

by Saloni Doshi • published July 3, 2025 • 22 min read

Guide to Sustainable Inner Packaging

EcoEnclose inner packaging solutions separate your goods, provide protection in transit, and present your products beautifully.

Table of Contents

- Sustainable Inner Packaging Products

- Mid Read: Quick Summaries on Carbon Footprint Reduction

- Long Read: Guide to Choosing the Right Poly Bag Alternative

- Where to Begin

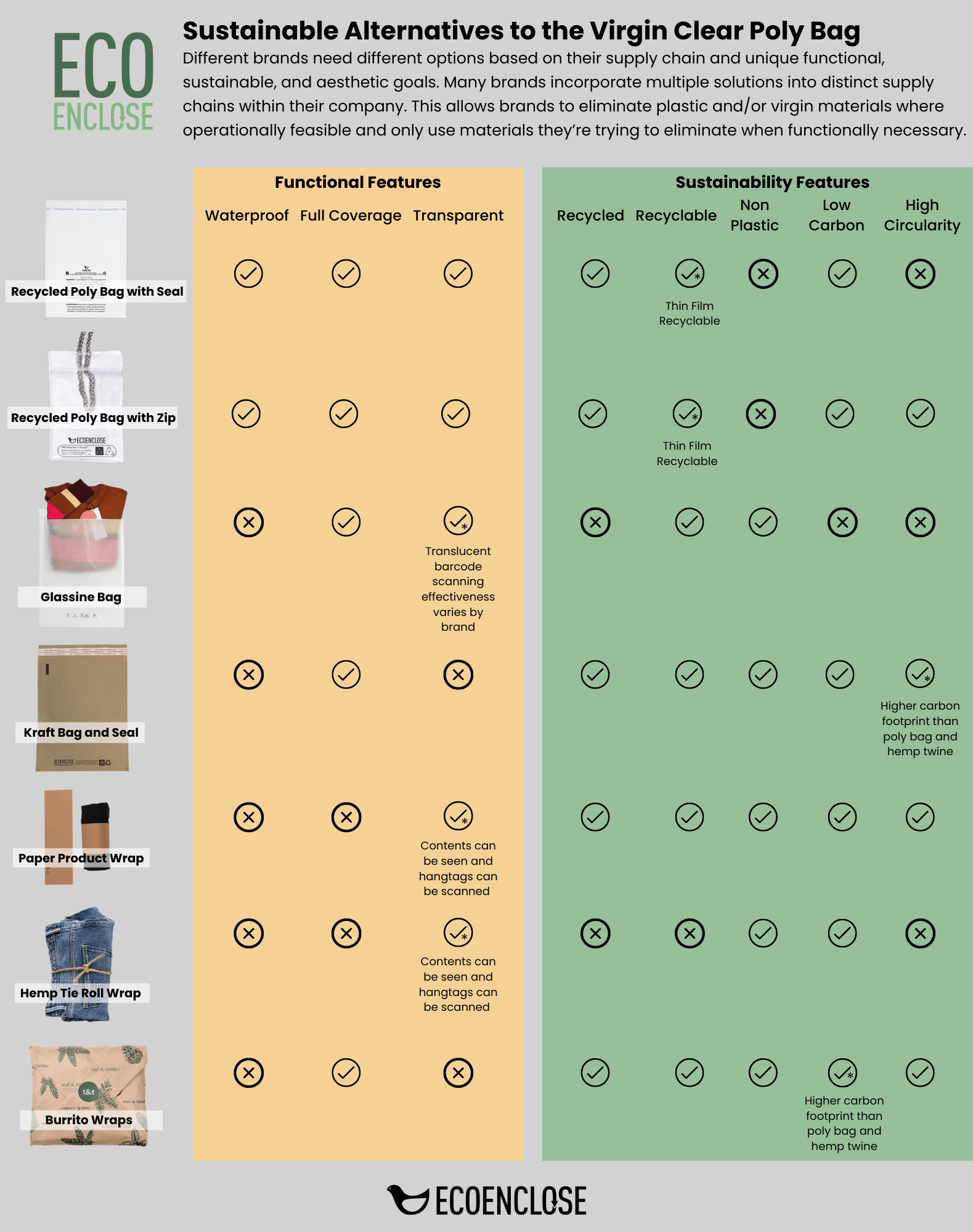

- Packaging Functional and Sustainability Scorecard

- Choose Solutions That Fit Your Supply Chain

- Solutions by Logistics Model and Sustainability Goals

- Testing and Implementation

- Sustainability Considerations

- Avoid These Materials to Prevent Greenwashing

- Reducing Plastic Waste in Your Supply Chain

- Communicating Your Sustainability Choices to Consumers

- Conclusion

- Work With Us!

- Helpful Resources

by Saloni Doshi • updated July 3, 2025 • 22 min read

A groundbreaking alternative to the virgin clear polybag. Made with seaweed, plants, and home compostable polymers.

Protect items from dust, dirt, moisture, and scratching. Adhesive closure. Available with suffocation warning. 100% post-industrial waste.

Protect items from dust, dirt, moisture, and scratching. Zipper closure. Available with suffocation warning. 100% post-industrial waste.

Curbside recyclable alternative to a clear poly bag. Translucent with a resealable adhesive strip. FSC® certified virgin paper.

Curbside recyclable alternative to a clear poly bag. Acid-free paper, open-top construction. 100% recycled, 90% post-consumer waste.

Provides bracing in a shipping box and light protection when wrapped around products. 100% recycled, 30% post-consumer waste.

Curbside recyclable alternative to a clear poly bag. 80# Kraft paper keeps goods secure. 100% recycled, 30% post-consumer waste.

FSC® certified paper protects against scuffing and dust. 100% recycled, 20% post-consumer waste. Custom brand with your design.

Wrap products in Packaging Paper or GreenWrap and tie with twine to give a unique and earthy presentation. 100% renewable hemp.

Mid Read: Quick Summaries on Carbon Footprint Reduction & More

Long Read: Guide to Choosing the Right Poly Bag Alternative

Many apparel brands we work with have begun the process of rethinking and replacing the ubiquitous virgin polybag - the clear, thin-film plastic bag that protects virtually all apparel from damage, moisture, and dirt. In recent years, consumers have expressed growing disappointment with the amount of plastic packaging that arrives in their eCommerce orders. Brands have responded by launching internal initiatives to reduce single-use plastic packaging, and in some cases, joining larger coalitions (like prAna’s Responsible Packaging Movement) with the same goal.

While the impact of packaging typically makes up a very low percentage of a piece of apparel’s overall environmental and carbon footprint (usually < 5-7%,) it has become the first impression for consumers of a brand’s overall sustainability strategy.

We are major proponents of improving the sustainability of your packaging suite, but we also recognize the massive undertaking this often entails: how do you shift an entire system from one material to another? How do we ensure our products and customers don’t pay the price of making strides toward better product sustainability?

In our experience, the type and scope of inner packaging that an apparel brand can adopt can be best determined by considering the following three factors for your brand, in order of priority:

- Your Logistics Model

- Your Functional Packaging Requirements

- Your Sustainability Framework and Goals

Brands often begin this process with the opposite approach - thinking about the packaging solution they want to use, and trying to fit that packaging solution into their supply chain.

Our recommended approach solves for three critical realities of your business first- the way your product supply chain is laid out; the functional needs that your packaging must align with; and the framework of sustainability goals most important to your company. Then select your potential solutions and begin testing.

Removing the polybag entirely can be challenging and can feel like a time-intensive priority to tackle.

Here we share the existing and upcoming product alternatives on the market, sustainability considerations, best practices for phasing out and replacing polybags, and strategies to reduce the overall amount of single-use plastic (used and wasted) in your supply chain. We hope this guide can provide you with a starting point for how to tackle the puzzle of inner packaging in the apparel and soft goods world.

Source: EcoEnclose

Where Do I Begin?

When it comes to finding and implementing sustainable packaging - there are no silver bullets that will be applicable and appropriate for every situation. We encourage brands to bring patience, grace, and understanding to the table whenever they begin a new project or initiative to implement a sustainable packaging suite. It will take time, testing, iterating, and lots of learning to get to the finish line - and that’s normal!

As we learn more and more about materials’ life cycle footprints, and as technology and products evolve, we can expect things to change again and again. At EcoEnclose, we often remind ourselves and our customers to focus on progress over perfection.

Jumping into the world of alternative polybag products on the market can be overwhelming if you don’t clearly understand your goals for phasing polybags out (short and long term) and the functional needs of your packaging.

Some questions we pose to help narrow this down are:

Does the packaging need to be:

- Waterproof?

- Transparent or translucent?

- Covering the entire product (full-coverage protection)?

- Dust and dirt proof?

- Tamper evident?

- Flat packing compatible/lays flat?

- Compatible with conveyor belt systems/distribution machinery?

Can your finished and packed apparel:

- Be rolled? I.e. roll packing / tied with hemp or raffia twine/burrito wrapped?

- Be folded differently to reduce the size of packaging needed?

- Be packed without individual polybags, but roll-packed and added to a master carton with a master polybag? (i.e. for shipments sent to retail locations.)

- Use different materials based on the segment of apparel (polybags for white or delicate items, paper bands for remaining apparel?)

What are your needs for:

- Packing speeds?

- Per unit costs?

- Custom branding?

What is your sustainability framework or clear environmental goals?

- Low carbon footprint?

- Curbside recyclable packaging?

- Plastic-free?

- Circular - made with recycled content?

Once you have answers to these prompts, take a look at Matrix 1: Packaging Functional and Sustainability Scorecard to see which options may fit your needs.

Source: EcoEnclose

Packaging Functional and Sustainability Scorecard

| Products | Recycled Polybag | Glassine Bag | Kraft Bag | EcoBand Paper Wrap | Reusable Bag | Hemp Twine | Tissue Paper | Paper Burrito Wrap |

| Transparent (for scanning) | Y | Y | N | N | N | N | Y (color dependent) | N |

| Water resistant/proof | Y | N | ||||||

| Dust and dirt proof | Y | Y | N | N | N | N | N | N |

| Tamper evident | Y | Y | Y | N | Y | N | Y | Y |

| Full coverage protection of product | Y | Y | Y | Y | N | N | Y | Y |

| Flat packing compatible / lays flat | Y | Y | Y | N | Y | N | Y | Y |

| Compatible with conveyor belt systems/distribution machinery | Y | N* | Y | N | Y | N | Y | N |

| Fast packing speed | Y (wickets available for faster packing) | Y | N* | N | N | N | N | N |

| Made with recycled content | Y | N | Y | N | N | N | N | N |

| Curbside recyclable | N | Y | Y | Y | N⊿ | N | Y | Y |

| Recyclable elsewhere | Y - thin-film dropoff, EcoEnclose Poly Take Back | - | Y | Y | N | N | Y ** | Y |

| Low carbon footprint | Y | N | - | - | N⊿ | N | N | - |

| High materials circularity potential | N | N | N | N | N | Y | N | N |

| Custom branding | Y | Y | Y | Y | N | N | N | Y |

| Y | Y | Y | N | Y | Y |

* The vast majority of distribution and production conveyor belt systems favor the use of plastic over paper materials - simply because the flexibility of plastic reduces the likelihood of damage to the apparel packed inside as it drops, tumbles, and moves through the system. More brands have begun testing paper alternatives, like glassine and kraft bags, in these same systems - we don’t yet have definitive data on the performance of these options in terms of damage rates, but can estimate that they are likely higher than damage rates for polybags.

** Tissue paper is recyclable in about 50% of municipalities. For Raffia, cloth, and when tissue is not recyclable - those materials can be home composted as long as they are not dyed or heavily printed.

⊿ Typically, cotton wraps or bags are not made with recycled textile fibers. If you can source recycled textile material from a transparent and certified supply chain, awesome!

Similarly, recycling textiles can be tricky- it’s hard to verify a quality designated and responsible downstream use or recycler for many textile recycling streams at present. While we are very excited about emerging reusable packaging options, we do not necessarily see them as the best ecological option in many situations. Research published in 2021 from Fashion For Good shows how thoughtful we need to be here.

For example, considering reusable mailers versus single-use mailers, when measuring impact by carbon emissions, a reusable package will be less sustainable (even if returned 100% of the time) than a 100% recycled poly mailer used twice. The material and carbon footprint to create a reusable mailer - like a polyester - is significantly higher than the footprint to make a single or double-use disposable mailer.

Source: Unsplash

Choose Solutions That Fit Your Supply Chain

It's important to use your logistics model as the foundation for your decision-making for packaging procurement - doing so ensures that whatever new solution you choose will be applicable and immediately adoptable by your supply chain and partners. We recognize that there are many kinds of logistics models for apparel and consumer goods brands, and each different model presents unique benefits and challenges.

| New Column | New Column | New Column |

| Large Brand Fully Automated and Outsourced | Mid-Sized Brand Some Outsourcing / Automation | Small Brand Printed In-House |

| Manufacturing and distribution are outsourced to partners in multiple locations. High levels of automation & conveyor systems in the supply chain. | Both production AND/OR distribution of products are outsourced to partners. Little to no conveyor distribution. | Production and distribution all happen in-house. |

For example, the creation of apparel for a small brand or Etsy shop owner has a relatively small footprint in terms of the location it’s produced, readied for shipment, and sent to customers. Many times, it occurs almost entirely in one location.

Compare this to a multi-national or global brand, who utilizes finished goods factories and contract manufacturing facilities in many different countries and even continents. Possibly, they own a portion of their manufacturing or distribution locations. They likely also utilize several distribution centers (DCs) in multiple locations, which pick and pack customer orders and ship them out. In many cases, these large supply chains utilize a variety of automated machinery and fulfillment processes, not to mention much more movement of goods along mechanical lines and conveyor belts. This brand has many more variables to consider in a massive overhaul of packaging than others.

Still, the majority of brands are somewhere in the middle - they use partners for either one or both of their manufacturing and distribution aspects, allowing them to focus internal investments on brand strategy and growth. These brands have less direct control over the production, packing, shipping, and fulfillment of their products and customer orders, but work closely with their partners to test new packaging and processes.

Source: EcoEnclose

Solutions by Logistics Model and Sustainability Goals

Plastic-Free eCommerce Packaging

Fully Automated and Outsourced

- Paper products have inherently less give and flexibility than plastic - which makes their movement on distributed systems and conveyor belts more prone to damage, and thus damaging to the apparel. If your products sustain lots of movement and long drops between conveyors, polybags may be the best option.

- Testing paper alternatives in significant volumes and at multiple locations is necessary to first determine the feasibility of replacing polybags with paper bags. Test for damage rate of apparel (dirt, tears, etc.) We recommend testing at least 500 bags, ideally more depending on your throughput volumes.

- Kraft Bags are not translucent for scanning, but UPC/barcode stickers can be applied to the outside of the bag.

Some Outsourcing / Automation

- Allows for scanning (transparent paper) and is curbside recyclable.

Kraft Bags

- Made of 100% recycled content (with high levels of PCW), curbside recyclable, and naturally biodegradable.

Raffia or Hemp Ties, EcoBands

- To protect apparel on its way to a DC, when roll-packing and using minimal packaging materials, place roll-packed apparel into one master polybag, inside of a master carton. This reduces the polybags used significantly, while still protecting apparel in preparation for fulfillment.

- Roll packing typically requires more time to complete than flat packing - ensure this is feasible for your process.

- Roll packing may be a more efficient way to pack master cartons of apparel for shipments to brick and mortar / retail channels.

All In-House

- Kraft Bags

- Glassine Bags

- Raffia or hemp ties

- EcoBand Product Wrap

- Cloth Bag / Wrap

- Tissue Paper

- Paper Burrito Wrap

Carbon Footprint Reduction (applicable to all logistics models)

100% Recycled Polybags

- The carbon footprint of producing plastics (especially LDPE) is significantly smaller than producing paper - even recycled content paper. This is due to the material weight (much smaller for poly than paper) and the amount of energy needed to produce the material in the first place.

- Use recycled LDPE in your polybags for an even lower footprint, and a boost to the circularity of the product.

Hemp / Raffia Ties:

- Depending on if this works with your logistics model.

Reducing Overall Plastic Footprint

Fully Automated and Outsourced

- Right-sizing (reducing the size of generic bags to what is truly needed for your apparel) polybags, and adjusting the folding method of apparel so smaller bags can be used is the method Patagonia used.

- Downgauge polybag film thickness (i.e. from 2.0 to 1.5 mil) to reduce the overall volume of plastic.

- If your systems (conveyors and automated lines) would support the use of paper bags like Glassine or Kraft partner or segmenting your product packaging, using polybags for only a portion of products that can’t be packed in paper (i.e. large, bulky apparel.)

- Work with your DCs and supply chain network to collect polybags from your apparel and processes. Work with a local recycler, or EcoEnclose, to recycle these polybags en masse in a thin film stream and ensure they are properly disposed of, and able to be recycled into new materials.

- Prompt customers at online checkout whether they want polybags or plastic packaging included in their shipment. This will give you a good idea of the percentage of your customers that are ok with no plastic in support of sustainability goals.

Some Outsourcing / Automation

100% Recycled Polybags

- Right-sizing (reducing the size of generic bags to what is truly needed for your apparel) polybags, and adjusting the folding method of apparel so smaller bags can be used is the method Patagonia used.

- Downgauge polybag film thickness (i.e. from 2.0 to 1.5 mil) to reduce the overall volume of plastic.

Plastic Film Collection:

- Inquire with your 3PL/fulfillment partner to learn whether they have an existing system for collecting polybags to recycle.

- If you’re managing order fulfillment and shipping to customers directly, ensure you have a collection point for plastic film, and your team is well-trained on how to recycle thin-film, separate from other curbside recyclables.

Collaboration with other brands, your 3PL, and Manufacturing partner(s):

- Great minds think alike! Often, similarly-focused brands (such as those who use organic cotton inputs or produce in a fair trade facility) have their goods produced or shipped in the same facilities! Inquire with your manufacturing and 3PL contacts to learn if other like-minded brands working with them, who may be open to collaborating on a large PO of plastic-free packaging alternatives, testing new packaging with you, or combining polybag recycling for a more significant effort for thin-film recycling.

All In-House

100% Recycled Polybags

- Use when totally necessary (i.e. for white or delicate apparel) and paper or wrap alternatives for the rest.

Paper / fiber-based alternatives:

- Kraft Bags

- Glassine Bags

- Raffia or hemp ties

- EcoBand Product Wrap

- Cloth Bag / Wrap

- Tissue Paper

- Paper Burrito Wrap

Materials Circularity (made from recycled content and readily recyclable)

Fully Automated and Outsourced

- Polybags and thin-film materials can be difficult to label “circular” - even if they are made with recycled content. Since their recycling is less accessible (most Americans don’t have access to thin-film recycling in their curbside pickups) thin film is recycled at a much lower rate than curbside-accepted materials. Encourage your customers to participate in recycling their thin film, either through custom-branded packaging, notecards or inserts, or through take-back partnerships like TerraCycle.

- Work with your DCs and supply chain network to collect polybags from your apparel and processes. Work with a local recycler, or EcoEnclose, to recycle these polybags en masse in a thin film stream and ensure they are properly disposed of, and able to be reused for new materials.

Kraft Bags

- Assuming they work well in your logistics model, these bags are a great circular choice. They’re made with 100% recycled content, (with high levels of PCW), are curbside recyclable, and are naturally biodegradable.

Some Outsourcing / Automation

100% Recycled Polybags

- Polybags and thin-film materials can be difficult to label “circular” - even if they are made with recycled content. Since their recycling is less accessible (most Americans don’t have access to thin-film recycling in their curbside pickups) thin film is recycled at a much lower rate than curbside-accepted materials. Encourage your customers to participate in recycling their thin film, either through custom-branded packaging, notecards or inserts, or through take-back partnerships like TerraCycle.

- Work with your DCs and supply chain network to collect polybags from your apparel and processes. Work with a local recycler, or EcoEnclose, to recycle these polybags en masse in a thin film stream and ensure they are properly disposed of, and able to be reused for new materials.

Kraft Bags

- These bags are a great circular choice. They’re made with 100% recycled content (with high levels of PCW), are curbside recyclable, and are naturally biodegradable.

EcoBand / Paper Product Wrap

- Made with 100% recycled content, and curbside recyclable, these are an easy win. Add a custom recycled sticker to seal them for some extra branding!

Tissue Paper

- If your systems would support wrapping products in tissue paper for protection, this can be a great option. EcoEnclose offers 100% recycled tissue paper, which is also curbside recyclable in many locations in the US and always naturally biodegradable.

All In-House

100% Recycled Polybags

- Polybags and thin-film materials can be difficult to label “circular” - even if they are made with recycled content. Since their recycling is less accessible (most Americans don’t have access to thin-film recycling in their curbside pickups) thin film is recycled at a much lower rate than curbside-accepted materials. Encourage your customers to participate in recycling their thin film, either through custom-branded packaging, notecards or inserts, or through take-back partnerships like TerraCycle.

Kraft Bags

- These bags are a great circular choice. They’re made with 100% recycled content (with high levels of PCW), are curbside recyclable, and are naturally biodegradable.

EcoBand / Paper Product Wrap

- Made with 100% recycled content, and curbside recyclable, these are an easy win. Add a custom recycled sticker to seal them for some extra branding!

Tissue Paper

- EcoEnclose offers 100% recycled tissue paper, which is also curbside recyclable in many locations in the US and always naturally biodegradable.

Source: Unsplash

Testing and Implementation

Implementing new packaging into your supply chain is a process! Expect to test, test, and test again before switching fully over to a new supplier or packaging product. Many brands we work with plan the process of implementing a polybag replacement over 6 months to several years. The more variables in your supply chain, the longer the transition will take. That is normal. Work with a packaging partner to help you stay on track and determine what success looks like.

We recommend:

- Inquire with your upstream partners to learn if there are existing initiatives to move out the polybag in the factories where your products are produced, or distribution centers your orders ship from. If so, you may be able to collaborate with other brands for a larger sample set and faster data collection.

- Run ship and fulfillment tests - lots of them - before transitioning to a large volume of new packaging. Measure the amount of damage to products, poor appearance, and successful shipments. Make sure to test multiple product types - small apparel, standard size, large apparel, and bulky options - to get a good understanding of performance across your product suite.

- Start with a pilot and then build momentum. This can take the form of a segmented approach, where you use a new product for only a portion of your products, test and review, then move to other SKU families. For example, for brands switching from poly mailers to paper mailers, we often recommend switching the smaller sizes of mailers first - they are often the most similar in fulfillment speeds and processes to the existing mailers.

Source: EcoEnclose

Sustainability Considerations

The least sustainable packaging strategy is the one that results in damaged or unusable products. With any transition in packaging, we always recommend performing the due diligence of material and ship testing new materials to learn how well they work for your needs.

Circularity and Recycled Content

At EcoEnclose, our mission is to make eCommerce a more regenerative, positive force for the environment. For us, that means pushing for total packaging circularity: using as much recycled content (specifically post-consumer waste) as possible, and creating products that can be recycled within an existing infrastructure.

While we detail several products in this guide, some of which perform better than others in various logistics models, we are always advocates of using as much recycled content as possible in packaging for any given scenario and encourage you to source the highest levels of recycled content in your packaging wherever you procure it.

Shop Local

Sourcing packaging in locations that are geographically close to your finished goods factory or production location is another easy way to reduce the overall carbon footprint of your packaging procurement.

Determine What Plastics are Necessary and Which are Not.

While plastics can be a superhero for thousands of applications, they are also major contributors to litter, ocean pollution, and landfill space. Even still, plastics are an incredible material, and we recognize that few materials boast as many functional benefits. In the plastic realm, we have found great guidance from referencing the US Plastics Pact’s Problematic or Unnecessary Plastics decision tree.

Source: Unsplash

Avoid These Materials To Prevent Greenwashing

Some materials are, without question, better than others regarding overall sustainability “score.” Be sure that the new packaging materials and products you choose are, in fact, better than your current packaging.

We often hear of brands that choose to go plastic-free and, in doing so, choose to use paper packaging with unknown sources of origin that could be drawing from ancient and endangered forests or opt for PLA bioplastic—both of which we have chosen not to offer as products because of their degrading impact on the environment and waste management systems.

Some of the materials we stay away from using in eCommerce packaging include:

- Virgin Plastics

- Virgin tree-based paper, paperboard, or cardboard, when recycled fibers could (functionally) perform well.

- When the strength provided by longer fibers in virgin paper is needed (as it is with glassine bags), we avoid any virgin paper without verification that it does not pull from ancient and endangered forests. Opt for FSC® certified paper from responsibly managed forests instead, and if FSC® is not feasible, thoroughly vet sources of origin.

- Bioplastics made through conventionally produced, land-based monocrop farming. For example, we say no to bioplastics derived from conventional corn, cassava, potatoes, and sugarcane.

- Plastics with biodegradability additives, particularly additives solely designed to accelerate landfill biodegradation

- Oxo Biodegradable plastics

- Dissolvable plastics - these are unlikely to deliver on your functional needs, are more linear than 100% recycled plastic film, and, at high volumes, wreak havoc on wastewater treatment.

*Note: EcoEnclose is a policyholder for Canopy’s Pack4Good initiative, where we commit to not using tree-based fibers for packaging that are sourced from ancient or endangered forests. We highly recommend using Canopy’s Paper Steps.

Bioplastics in eCommerce

Bioplastic is an umbrella term for packaging either 1.) made from bio-based sources (like plants), or 2.) able to biodegrade (to industry standards) in a home or industrial compost environment, or both.

Examples are PLA Shipping Mailers and PLA Clear Poly Bags, Corn Starch Packing Peanuts, Oxo-biodegradable plastics, and plastics with biodegradable additives.

Some bioplastics should be avoided in general. We believe corn-based bioplastics are an example of this.

PLA is the most popular and cheapest bioplastic in the world today. It is made with industrial corn - a crop that wreaks havoc on waterways and soils and relies heavily on fossil fuels to produce. Additionally, only 4% of Americans have access to industrial compost streams or facilities in their locales, so this packaging is frequently incorrectly recycled (also known as wish-cycled) or landfilled - where it breaks down over time to create methane pollution.

Most of these bioplastics do not break down if leaked into the natural environment as litter, so they do not solve our ocean plastic crisis. Finally, even when Americans can compost their eCommerce packaging, their local composters do not want low-value inputs that degrade their compost, making selling more difficult.

However, a small subset of emerging bioplastics poses environmental promises—such as seaweed-based films, certified sustainably grown sugarcane-based plastic, and plastic derived from food or ag waste.

EcoEnclose continuously searches for the most environmentally promising bioplastic options being developed today while actively rejecting solutions whose source inputs are likely to harm the planet. We have seen that bioplastic polybags and mailers chosen without regard to the material’s source inputs are a top contributor to greenwashing in eCommerce packaging.

Learn more in these resources:

Source: Unsplash

Reducing Plastic Waste in Your Supply Chain: Creative Options

There are many (and more every day) creative solutions that brands have utilized to reduce the overall plastic footprint of their supply chain and to divert necessary plastics from the landfill. A few to note are:

- Streamlining collection of polybags at your DCs and finished goods factories, and recycling them properly with a waste management recycling partner, or through EcoEnclose’s poly takeback program.

- If roll-packing with paper bands, raffia, or hemp ties is feasible for you, these rolled pieces can be packed into a master carton, and protected in bulk with one large plastic bag lining the box. This is especially applicable for shipments going to brick-and-mortar retail channels. Some brands find that they can pack higher volumes of apparel into master cartons when it’s rolled, versus packed and stacked flat.

- Down-gauging the thickness of plastic being used, both polybags and poly mailers. By moving from a 3.0 mil to 1.5 mil, you can halve the gross volume of plastic used for your packaging.

- Try folding your apparel into a smaller footprint, to allow you to use a smaller polybag and reduce the amount of plastic needed at the source.

- Offering customers the chance to choose, at checkout, whether they would like plastic packaging or paper packaging. For customers and brands who are committed to removing the polybag from shipments, you may be able to instruct your DC or 3PL to unpack each item from its polybag before sending it in its secondary (shipping) packaging. In this case, the 3PL can then streamline the collection of polybags, and ensure their responsible recycling. Keep in mind that this added step of unpacking will add time to the fulfillment process - assess whether this is feasible for your budget and throughput goals.

Source: Unsplash

Communicating Your Sustainability Changes and Choices to Consumers

No matter what packaging you opt to transition to and include in your fulfillment, make sure you make an effort to communicate this change to your customers. This will clue them in to your thoughtfulness, variables in your supply chain, and your overall sustainability framework for packaging. According to Shopify's 2021 Future of Ecommerce report, 73% of consumers are more likely to buy a product packaged sustainably. Many will also pay a premium.

Include communication to your customers about your packaging decisions, your reasoning, and your choice of material. Be sure to include the proper disposal instructions for the packaging, as well - how to recycle, reuse, or bring to a thin-film drop-off recycling stream.

You can communicate this information through custom printing your packaging directly, adding in an insert or notecard, or including these details on your website and social media presence.

Example:

Before reaching you, this product traveled through our supply chain and multiple continents! To keep it in great condition for your first impression, we chose to use this polybag for the ultimate protection. It’s made with 100% recycled content (PIR). Please either reuse this bag or recycle it in thin-film recycling streams - found at most grocery and big-box stores.

We’re on our way to plastic-free packaging! To do so, we’re testing out these glassine/kraft bags instead of a typical plastic polybag. Please give us quick feedback (via a QR code/website) on how this arrived, and your satisfaction with this shipment!

Source: EcoEnclose

Conclusion

Assessing and evolving your internal packaging products can be a massive undertaking and one that more brands than ever are taking on. Rest assured that it is possible to make improvements in supply chain sustainability, no matter your specific logistics style or product set.

We highly recommend working with a packaging partner, like EcoEnclose, when confronting these new initiatives. They can provide you with expertise gathered from conversations with hundreds of brands like yours, and give you feedback on your testing and implementation processes.

Work With Us!

We always want to partner with conscious brands, and those navigating the nuance of transitioning to sustainable packaging throughout their supply chain. We would be thrilled to work with you. Contact us and learn more at:

[email protected] // 888-445-6575 // www.ecoenclose.com // @ecoenclose

Helpful Resources:

- EcoEnclose Guide: Transitioning from Poly to Paper Packaging

- EcoEnclose Guide: Moving your Fulfillment Center to a Sustainable Packaging Strategy

- US Plastics Pact: Problematic and Unnecessary Materials List

- Fashion For Good - Polybags in the Fashion Industry Evaluating the Options

- prAna's Responsible Packaging Movement

- Patagonia's Plastic Packaging: A Study on the Challenges of Garment Delivery

- Canopy's Paper Steps

- Canopy Pack4Good

Product Links:

About EcoEnclose

EcoEnclose helps forward-thinking brands deliver on their sustainability goals with innovative, research-driven packaging solutions designed for circularity.