Eco Friendly Stickers & Product Labels

ECO FRIENDLY STICKERS AND PRODUCT LABELS

Looking for eco friendly stickers? You've found the most sustainable options on the market. EcoEnclose offers two earth-conscious sticker lines delivered on sheets, rolls, or as individual die-cut starting at just 250 units.

Art Requirements | Proofing Process | Lead Time

Review our artwork guidelines; these serve as an overview of our sticker's printing parameters. Still have questions? Contact us - we are happy to help.

Use our templates to place and size your artwork to your specifications. Use your original art file or your designed template when placing your order.

We have a real, live human review and proof your artwork prior to production. Look out for your digital proof within 1-2 business days after your order is placed.

Lead time begins after digital proof approval. Check out our current lead times here.

Contact Us - We are happy to answer any questions about our custom printing services. Learn about our advanced sticker printing options; including kiss cut stickers and using multiple designs towards one order quantity.

Want to go fully branded with your packaging? Check out all of our custom packaging options for more info.

Request a Quote for a Custom Shape or Size

Which Facestock Is Right For Your Eco Friendly Stickers?

With six facestocks to choose from, feel confident you'll have the perfect sticker for every occasion.

The World's Most Sustainable Stickers

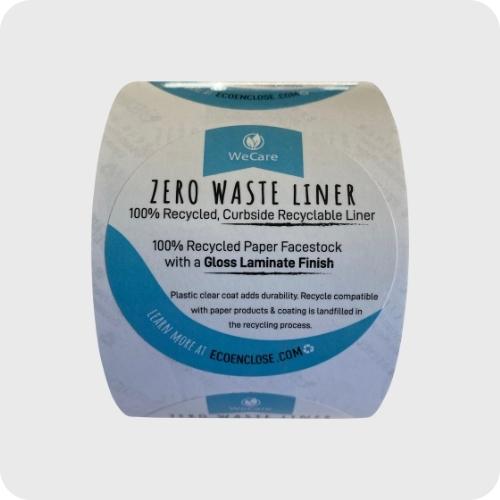

Zero Waste Liner

Our Zero Waste stickers feature our unique release liner, made from 100% post-consumer waste, and curbside recyclable with paper products.

Paired with a 100% post-consumer waste uncoated paper facestock, you're looking at the world's most sustainable sticker.

Facestock Family

We have six facestocks ranging in durability for the perfect sticker for every occasion. Five of our six facestocks have 90 to 100% post-consumer waste content.

Looking for our most eco-friendly facestock? Shop uncoated paper which is 100% post-consumer waste paper.

Recycle-Compatible Adhesive

Our recycle compatible adhesive is screened out during the paper recycling process whereas traditional adhesive is a contaminant to the paper recycling stream.

Our recycle compatible adhesive ensures our paper stickers are friendly additions to the paper recycling stream.

Made in North America

Our Zero Waste stickers are produced in Canada and the USA. Our Standard stickers are produced in the USA.

We prioritize building a domestic supply chain and we choose domestic partners whose eco values align with ours as part of our Sustainable Packaging Framework.

Inspiration

Frequently Asked Questions

About Designing Eco Friendly Stickers

Why are there two release liners?

What are your artwork guidelines?

Can I print multiple designs in a single order quantity?

What is the lead time?

Can I use stickers to seal boxes?

What stickers pair well with glass or aluminium?

Can I order sticker samples?

Can I order blank sticker sheets?

What are stickers?

Most of us are familiar with stickers. You find them everywhere - sold at merchandise tables, wrapped around bottles of household products, and stuck to grocery produce, just to name a few. In this article, we discuss custom stickers - pieces of paper, plastic, or other materials with adhesive on one side and a custom design on the other.

While stickers and labels are technically the same things, they are used in different ways. Stickers are typically for marketing, promotion, decoration, celebration, community building, art, and general creativity. Bumper stickers, “I Voted” stickers, decorative stickers for water bottles and laptops, kids sticker books - these are all examples of fun, decorative stickers. On the other hand, labels is typically used for more functional applications. Most products need to carry labels with product names, ingredients, safety information, etc. Labels - such as shipping and UPC labels - are critical packaging supplies for logistics and delivery.

For stickers and labels to be truly eco-friendly, we believe they should be created as closely as possible to our Sustainable Packaging Framework.

Recycled Content:

Seek stickers with recycled content, and as much post-consumer waste as possible. Learn why recycled content matters.

The majority of EcoEnclose stickers are made with 90-100% recycled content, all of which is post-consumer waste.

Recyclable:

There are multiple components to every sticker - from release liner to adhesive to facestock to ink to finish. Choose stickers that have as many recyclable or recycle-friendly components as possible.

All EcoEnclose stickers use a recycle-compatible adhesive, and our paper stickers are easily recycled in the same stream as paper and corrugate when adhered to those surfaces.

Zero Waste:

As we strive towards a more circular economy, keep in mind the smallest of packaging materials. Specifically, the sticker release liners which are notoriously difficult to recycle.

The majority of EcoEnclose stickers are delivered on our unique and innovative Zero Waste release liner which is made of 100% recycled paper and is curbside recyclable - the first and only release liner of its kind.

Watch EcoEnclose Sticker Overview

How do I choose a sustainable sticker?

Choosing the most sustainable sticker for your unique need is not always a straightforward decision process. Keep in mind the four sticker components described below, and remember to select a sticker that best suits the end-of-life of the substrate.

Facestock

Wherever possible, choose 100% recycled (ideally 100% post-consumer waste) paper facestock. One-hundred percent recycled paper is almost always your most sustainable sticker choice. However, if durability and weatherproofing are critical, your options include recycled polypropylene stickers or coated 100% recycled paper stickers. When working to ensure your facestock is as eco-friendly as possible, seek facestocks with the highest level of recycled content (and post-consumer waste) possible.

EcoEnclose stickers are designed for recyclability, but not in isolation. It is important to select a facestock to support the recyclability of the substrate.

Uncoated Paper Stickers

A 100% post-consumer waste paper facestock. The base for our varnish and laminate stickers.

Varnish Stickers

A tough, plastic-free clear coat with a matte finish that enhances the brilliance of the ink.

Matte Laminate Stickers

A plastic laminate film with a matte finish that adds sheen and vibrancy to the ink.

Gloss Laminate Stickers

A plastic laminate film with a glossy finish that adds sheen and vibrancy to the ink.

Release Liner

Choose 100% recycled, curbside recyclable Zero Waste release liners when feasible. When this is impossible, ask for release liners made with recycled content (and high levels of post-consumer waste) and release liners that can be recycled. Many release liners may not be curbside recyclable but could be compatible with hard-to-recycle streams.

Adhesive

If you have optimized the sustainability (recycled content in particular) of the above two components, you’ve tackled the most important questions to help you find an eco-friendly custom sticker. When it comes to adhesives, acrylic emulsion adhesives are typically the most eco-friendly due to their manufacturing process and their recycle compatibility. While hot melt adhesives and rubber adhesives are less friendly to the recycling process, they do not generally render packaging unrecyclable unless the stickers cover most of the package.

Printing Inks

The world of printing inks can be very complicated. The main factor driving the use of specific printing ink will be the printing method, which your order volume typically dictates. Your most important question should be to confirm that the ink used for your stickers does not contain harmful solvents as their carrier.

Delivery Methods: Sheets, Rolls, and More

Sheet Stickers

Standardized sheets refer to sheets with the same sticker shape and design repeated. Sheets are easy to store, making them an efficient delivery method for companies using stickers as part of their product or shipping packaging. Because multiple stickers come on the same sheet, this is not a great method for companies that are handing out individual stickers to their customers. Variable sheets refer to sheets that include a variety of different sticker designs or shapes. These are great to use for marketing - as additions to packaging or handouts at events.

Roll Labels

Labels on rolls are often used with manual or automated dispensers, making them an ideal option when you need to apply stickers quickly. They are also more cost-effective than sheets at high volumes. Rolls can be perforated between stickers, so companies can tear them off and give them away one at a time.

Die-Cut Stickers

Die-cut refers to stickers whose backing aligns perfectly with the shape and size of the sticker itself. The result is a sharp-looking sticker even before the sticker is removed from its backing. Die-cut stickers often feature a cut in the backing to allow the backing to peel away easily.

Kiss Cut Stickers

Kiss cut stickers are similar to die-cut stickers in the sense that you end up with an individual sticker. However, only the sticker is cut to shape, leaving the backing intact. This results in a margin between the sticker and the edge of the backing. Kiss cut stickers are often easier to peel away from their backing than die-cut stickers, and the extra backing can help protect delicate designs.

Facestocks: Paper, Vinyl, and More

Facestock refers to the substrate of the sticker itself, and there are many different options for facestock across sticker and label companies. Here, we discuss the most popular options.

Paper:

Paper is the most common and simple facestock on the market. Virgin or recycled paper can be used, but the most sustainable options are made from 100% recycled, 100% post-consumer waste paper. It tends to be the least durable against moisture and general wear but it is often the most cost-effective and sustainable. Enhance their durability with a finish - UV varnish and laminate are popular options.

Vinyl:

Vinyl, a plastic known as polyvinyl chloride (PVC), provides a slight flex and stretch in the material that enables it to be easily applied to both flat and curved surfaces. It is also very durable, holds up well to moisture and oil, and feels smooth to the touch.

Polypropylene:

More commonly known as BOPP (biaxially-oriented polypropylene), this plastic facestock is known for its strength and durability. BOPP has a great clarity that makes it a good option for clear labels, and it is also available as opaque in different colors, the most common being white. This thin and flexible material is very moisture and oil-resistant as well.

Bioplastic:

Like other plastic stickers, bioplastic stickers are strong and durable. Bioplastic is plastic derived in part or fully from plants or other rapidly renewable materials. This type of plastic can be certified compostable, recyclable with traditional plastic, or only suitable for the landfill. Bioplastic can also be derived from petroleum and is certified compostable in either a home or industrial setting. Unfortunately, there is also bioplastic derived from petroleum and labeled as "biodegradable", but is not certified compostable.

Learn more: Bioplastic for eCommerce Packaging

Biostone:

Biostone is a paper-free material from calcium carbonate (stone dust) that is bonded together with a small amount of polyethylene (HDPE). Polyethylene is plastic (the same used to make plastic grocery bags) usually made from petroleum. These labels are not recyclable, 100% compostable, or 100% biodegradable.

Wood:

Perhaps not as popular as some of the others, wood stickers are traditionally made of wood, so it is important to ensure that the wood is sustainably and ethically sourced. Wood stickers will typically biodegrade in a natural environment.

Printing: Methods and Ink

Personalized stickers are printed in a variety of ways. It is important to note that you, as a company or customer, do not generally dictate how your order prints. Instead, you place your order and any specifications on the quality and durability you need in your stickers. The printer will then print your order on whatever machine or with whatever method they have that will best match the facestock, delivery method, quantity, and finishings you require.

Despite this, we believe it is valuable for eco-conscious companies to understand printing methods and the types of inks used within each printing methodology. Many thoughtful clients will ask, “are sustainable inks used”? We believe a more holistic and helpful question is, “can you tell me what printing methodology and printing inks will be used for my order?”

Digital Printing

Digital means that an electronic image file is converted directly into the image, and the printer lays down dots and pixels to create the image you see on a screen. Digital printing is most often used for low-volume quantities though the definition of “low-volume” differs based on a print shop’s setup. In a diversified print shop, a run for a single art file of more than 10,000 or so units will result in the order shifting from a digital press to an analog press. Digital printing requires no real setup and allows for quick turns from one art file to the other. Because of this, many printers will gang-run their orders meaning they will group all orders for a single sticker size together, and the software will change over the art throughout the run.

Digital Dry Toner: This is similar to a toner printer you would have at home but, in most commercial establishments, would be done at a much larger scale. These printers use dry toners that are pigments encapsulated in resin (tiny plastic particles) instead of liquid ink. This pigment fuses onto the surface of the substrate using heat.

Despite the resin, toner printing is, in some ways, very eco-friendly because it emits no toxins into the environment and has a high-efficiency transfer rate. Very little waste is created, and there is no ink to discard at the end of the process. Almost all the pigment is used for artwork, whereas other printing inks have a carrier that evaporates during the process. Toner ink can be de-inked by recyclers and repulpers making it a suitable ink for products destined for recycling. Additionally, toner cartridges are typically collected by their manufacturers and reused.

Ink(s) used: Dry, digital toner pigments (no carrier).

Digital Liquid Toner: i.e. HP Indigo ElectroInk. This printer, which is becoming increasingly common in print shops, combines the concept of offset printing technology with digital toner technology. With the HP Indigo press, ink is transferred to a heated blanket which melts and blends the ink particles into a smooth film. The ink is then transferred to the facestock. The machine uses proprietary HP ElectroInk which contains charged pigmented particles encompassed in resin within a liquid carrier that is diluted with water or oil.

Ink(s) used: Resin encapsulated dry toner pigments immersed in a liquid carrier (water and/or oil).

Digital Inkjet: Inkjet is a common form of home printing, but it is not used frequently for commercial sticker printing. Ink sprays out from the printhead and absorbs into the facestock while some of the carrier evaporates. This printing method differs from toner, where pigments fuse into a facestock. Given this difference, inkjet printing may result in a slightly more faded look than toner.

Ink(s) used: Water-based pigment or dye inks.

Analog and Conventional Printing

Analog or conventional printing involves an electronic image file converted into a printing plate or screen. The printing press is set up with the plate or screen and the printing substrate. Ink is transferred to the plate and then onto the substrate. This type of printing typically produces higher-quality prints and closer color matching than digital printing.

Two types of analog printing, flexographic and offset, are extremely fast, making the per-unit cost lower than digital. However, the setup times are higher (often significantly high), making this printing less cost-effective for small runs. Flexographic and offset printing are used by many label companies (and a small set of sticker companies) for high-volume orders. Screen printing is typically reserved for a small subset of orders that require extremely high quality, finish, and durability.

Flexographic: An image is converted into a flexible, photopolymer plate that is an exact mirror of one color of the printed image. This plate is wrapped around a printing cylinder. Ink is then transferred from the ink well, onto an anilox roller, and onto the printing plate, which then prints directly onto the substrate.

Ink(s) used: Water or solvent-based inks. Additionally, innovative, eco-friendly inks such as Algae Inks are available, allowing for a renewable pigment.

Offset: Ink is transferred onto an aluminum printing plate, which prints the complete wet image onto a blanket, which then transfers the ink onto the substrate.

Ink(s) used: Solvent, soy, or vegetable-based inks. Additionally, innovative, eco-friendly inks such as Algae Inks are available, allowing for a renewable pigment.

Screen Print: An image is burned onto a screen. Ink is placed on top of the screen and scraped down, letting ink transfer onto the substrate below only where the image has been burned onto the screen.

Ink(s) used: Water, solvent-based, or plastisol inks. Additionally, innovative, eco-friendly inks such as Algae Inks are available, allowing for a renewable pigment.

Learn more about inks on our blog: What is the Most Sustainable Ink? | How Algae Printer Ink is Changing the Industry

Finishings: Lamination and More

UV Varnish Finish

UV Varnish is a tough, typically matte, plastic-free clear coat for eco-friendly protection and durability while enhancing the brilliance of the ink colors and protecting them against sunlight. This finish is recycle compatible when used on paper stickers and those stickers are placed on corrugated and paper products because the varnish disintegrates during the paper recycling process ensuring a clean recycling stream.

EcoEnclose varnish paper stickers are recommended over laminate paper stickers because the coating is plastic-free, making them an ideal option for a plastic-free packaging strategy.

Laminate Finish

Laminate is a glossy or matte plastic film for increased protection and durability while adding sheen and vibrancy to its ink colors. This finish is recycle compatible when used on paper stickers and those stickers are placed on corrugated and paper products because the laminate is skimmed off and discarded during the paper recycling process and the base of the sticker is recycled with the substrate. However, the laminate film may not always be removed completely and therefore is a potential contaminant to the recycling stream.

EcoEnclose laminate paper stickers are recommended over varnish paper stickers when you're looking for a paper sticker with more durability against moisture.

Holographic Finish

A hologram is a 3D image which is typically formed when multiple lasers or comparable light sources interfere. Something that is holographic involves multiple colors or light frequencies interacting with each other; so a hologram will typically produce a holographic image or reflection. Holographic stickers with a gloss finish provide the maximum holographic effect while matte finish has a more subtle holographic effect (Source: Sticky Brand)

Glitter Finish

A glitter finish on a sticker can be simulated with a foil hologram, or actual glitter flakes can be used, typically a super fine transparent metallic glitter. The latter can be left uncoated for a grainy texture or laminated for a glossy or matte finish that would preserve the longevity of the glitter and sticker.

Adhesives: Plastic-Free and Permanence

Recycle-compatible materials for clean recycling streams.

There are thousands of different adhesive formulations in the world. These formulations vary in strength, permanence, how well they work on varying substrates (metal and paper require different types of adhesive), how well they work in different temperatures, etc. Here we focus on the broad adhesive categories used for stickers, which require “pressure-sensitive” adhesives. This type of adhesive is tacky and needs pressure to bond with the substrate.

Permanent Pressure-Sensitive Adhesive

Stickers with a permanent adhesive are designed to be stuck to a surface and then not moved or removed. Most stickers in the market are designed with permanent adhesive because, in most situations, you want your label or sticker to remain affixed where you put it, long-term. These adhesives come in a few main categories.

Acrylic Emulsion: This adhesive is one of the most popular permanent adhesives on the market. Acrylic polymer adhesives are suspended in water, or less frequently, solvents. Those with water are the most common in the standard sticker market.

Hot Melt: These adhesives are polymers that melt when heated and are tacky when at room temperature. They typically create a stronger and more temperature-resistant bond than acrylic emulsion adhesives, making them an excellent choice for refrigerated or frozen food packaging. In some ways, they also offer environmental benefits to acrylic emulsion adhesive because they do not emit VOCs and do not require energy-intensive drying units in the label manufacturing process.

Rubber: These adhesives can be synthetic or naturally derived and offer a high initial tack. However, they often have a yellowish tint and do not peel off smoothly, making them more useful in an industrial setting over marketing-focused stickers.

Repositionable & Removable Pressure-Sensitive Adhesive

These adhesives enable a sticker to separate from its substrate. Stickers with repositionable adhesives are reusable because their adhesive remains tacky. Stickers with removable adhesives cleanly separate from their substrate because tackiness disappears after first use. Acrylic emulsion adhesives make up most repositionable and removable stickers.

The design of other stickers, such as static cling, enables them to adhere to glass or other smooth surfaces for easy repositioning.

Learn more about adhesives on our blog: Eco-Friendly Adhesives in the World of Sustainable Packaging

Release Liners: Importance of Recyclability

Recycled and recyclable release liners for eco friendly stickers.

A release liner is a material that carries a substrate with a pressure-sensitive adhesive until that adhesive is ready for its next step. It is sometimes called a backing or carrier.

Silicone-coated supercalendered virgin paper is the material traditionally used for release liners. The silicone coating gives the liner its release properties. Release liners can also be plastic film-based or made with metalized papers and foils as their base. All of these materials are either not recyclable or extremely difficult to recycle. A handful of manufacturers in the US have the equipment needed to recycle standard silicone-coated liners by separating the silicone from the paper so the paper can be recycled. More often than not, the landfill is where sticker release liners typically end up due to the materials used for most release liners on the market today.

EcoEnclose is proud to offer a unique and innovative release liner - the Zero Waste release liner - made with 100% post-consumer waste material and is curbside recyclable with paper products.

Learn more about release liners and why recycled release liners are important on our blog: What Are Release Liners?

End-of-Life: Recyclable, Naturally Biodegradable, Compostable

The end-of-life of eco friendly stickers.

Our stickers are designed for recyclability, but not in isolation. Select a facestock to support the recyclability of the substrate.

Many sticker companies offer disingenuous claims that their stickers are biodegradable, compostable, or recyclable. We say disingenuous because stickers rarely meet their end-of-life without being stuck to something. That something - whether it be a piece of paper, a shipping box, a plastic water bottle, a paper mailer, tissue paper, a laptop - is considered the primary package. When considering the end-of-life of a sticker, one must ask how stickers will impact the end-of-life of their primary packaging.

As long as stickers do not represent a large portion by size of their substrate, they will not change the end of life of that substrate. However, they do introduce some contamination that - if they represent too large of a portion of the substrate by weight - could cause degradation of the reclaimed material.

For example, if a poly mailer is covered end-to-end with paper stickers, reclaimers will find it more challenging to re-pelletize that poly material. If a large poly mailer contains a single 4x6" shipping label, the shipping label will have a negligible impact on the reclaimer's ability to pelletize the poly mailer.

For stickers that get placed on permanent items - like car bumpers or telephone poles - the question might be, how will this sticker behave exposed to the elements long-term? These stickers typically need to be made with a durable plastic facestock. However, durable plastic facestock is not going to biodegrade over time. The best hope for these stickers is that they remain intact long-term until their substrate is discarded, typically into the landfill.

Even though appropriately-sized stickers do not typically impact the end of life of their substrate, some facestocks are better than others. In most cases, a paper facestock sticker will have the most minimal impact on the substrate's end of life, though they offer the least durability. BOPP and vinyl are the most durable, but they will bring in the highest level of contamination to a recycling or composting stream.

Works Well With

Tissue Paper

100% recycled, 20% post-consumer waste. FSC certified 10# paper protects against scuffing and dust. Custom tissue paper is available.

Glassine Bags

FSC certified virgin paper. Curbside recyclable alternative to a clear poly bag. Smooth, translucent paper, resealable adhesive strip.

EcoBand Product Wrap

100% recycled, 30% post-consumer waste. Curbside recyclable alternative to a clear poly bag. 80# Kraft paper keeps goods secure.

Custom Shipping Boxes

100% recycled, 95% post-consumer waste. Fully customize style, size, strength, and branding, ensuring your product fits perfectly.