Eco-Friendly Adhesives In the World of Sustainable Packaging

Posted By on Apr 18th 2022

Eco-Friendly Adhesives In the World of Sustainable Packaging

by Saloni Doshi • published July 29, 2025 • 7 min read

You probably think of boxes and mailers when you think of shipping packaging. Maybe you think about tissue paper and bubble wrap. You might also think about tape.

But only the most packaging-obsessed among us think about the most detailed nuances of sustainable shipping solutions - things like printing ink, release liners on labels, and eco-friendly adhesives.

Since EcoEnclose is proud to be a true EcoGeek, we sit around thinking about and trying to find ways to create the most environmentally friendly adhesives. So if you're with us, read on!

What is an Adhesive?

Quite simply, adhesives are any substance that sticks two objects together—basically, glue. The objects stuck together by our adhesive are considered the "substrates." Ever made a grilled cheese sandwich? Once melted and cooled, the cheese could be considered an adhesive that holds the two pieces of bread (substrates) together.

Source: EcoEnclose

What Kind of Adhesives Exist?

There are so many different ways to think about adhesive categories.

For example, they can be characterized by how they form the bond between substrates.

- Drying. Some adhesives work by drying. Think rubber cement and Elmer's glue. In these types of adhesives, the substrates adhere after the solvent or carrier dries, and the adhesive hardens.

- Pressure-sensitive: This type of adhesive is solid enough to retain its shape but soft enough to flow and press into the substrate when pressure is applied. When that adhesive is pressed into the substrate, molecular interactions firm and strengthen the bond. The most common example of a pressure-sensitive adhesive is Scotch tape or any other brand of clear household tape. Post-it notes and Band-aids are also an example of pressure-sensitive adhesives. Often, when a pressure-sensitive adhesive is involved, a release liner protects the adhesive properties until it is ready to be used.

- Hot melt: A hot melt adhesive is a thermoplastic that is melted to become a liquid and then solidifies when cooled. Once hardened, the adhesive forms strong bonds between various materials. One of the most common examples is a glue gun and glue stick.

- Reactive: There is a wide range of glues in which the adhesive reacts with a substance (sometimes the actual substrate being adhered to), creating the bond. The most common example is a water-activated adhesive, such as a moistened envelope and then sealed. The water activates the adhesive - typically made with potatoes or corn starch - allowing it to stick to the paper.

Alternatively, adhesives can also be characterized by the raw materials used.

Some are made from renewable resources. Familiar natural sources of adhesives include starches (such as corn, potatoes, sugarcane, and wheat), natural resins (such as gum arabic), casein (a milk protein), and other animal sources (such as beeswax, shellac, and gelatin rendered from animal hides, hooves, or bones). Some are made from natural but non-renewable resources. These adhesives are made from amber, silica, and sulfur minerals.

Synthetic adhesives are derived from human-made polymers, including thermoplastics, thermosets, and elastomers. While more costly than natural adhesives, these types of adhesives offer more incredible bond strengths and durability and provide more options for customization.

Other ways to characterize adhesives include their form (liquid, paste, powder, solid) or how they are typically applied.

Source: EcoEnclose

Where do Adhesives Show Up in EcoEnclose Packaging?

Across our packaging solutions, there are several different places where adhesives show up, and we utilize a broad set of adhesives.

Adhesives are used to form corrugate for our 100% recycled custom shipping boxes. The liner board and fluting are glued together using a starch-based adhesive.

Adhesives are used to glue our RSC and FPF boxes. Note that our other box styles do not require any glue). These are hot melt thermoplastic adhesives.

Adhesives are used to form our recycled mailers. This refers to the glues that are used to create the mailers themselves. A water-based vinyl acetate-ethylene adhesive is used for most of our paper mailers. Our poly mailers and poly bags are heat-sealed, so no adhesive is used.

Self-sealing, pressure-sensitive adhesives are used on our mailers. This refers to the adhesive that you - the end-user - would use to seal the mailing envelope once you've put your products inside. These adhesives are covered with a release liner that you peel off to expose the adhesive for closing. These are synthetic polymer hot melts that form a pressure-sensitive adhesive for most of our paper mailers. These are acrylic-based adhesive coated on both sides for our poly mailers and flap and seals.

Adhesives are used on our stickers and shipping labels. This refers to the adhesive revealed when you peel the stickers or ship labels off its release liner to expose the adhesive and then adhere the tag onto a substrate. Our stickers and labels are acrylic emulsions (pressure sensitive) adhesive.

Adhesives are used on our pressure-sensitive tape. EcoEnclose offers two different types of pressure-sensitive tape - a cello and kraft flatback tape. Both of these tapes have a pressure-sensitive rubber adhesive.

Adhesives are used on our water-activated tape. Our water-activated (i.e., gummed) tapes have a wetted starch-based adhesive to activate the adhesive.

Source: EcoEnclose

What to Consider When Choosing an Adhesive

Functionality and Effectiveness

The right adhesive depends on the job.

At home, you’d never use the same glue for everything. A broken mug? Crazy glue. A kid’s art project? Elmer’s. Scrapbooking? Double-sided tape. Packaging is no different—each application demands the right adhesive.

Think about a Post-it note versus a self-sealing mailer. The low-tack adhesive on a sticky note would never hold a mailer shut.

Performance depends on two factors:

-

Formulation: Some adhesives stick well to metal but poorly to paper.

-

Application method: In our warehouse, we use hot-melt machines to glue corrugated boxes. The adhesive must harden within seconds. A slow-drying glue would leave piles of boxes waiting to set.

In short: the adhesive must work for the material and the process.

Sustainability and Health

Eco-friendly adhesives aren’t just about what they’re made of—they’re about how they behave.

VOCs (Volatile Organic Compounds): Drying adhesives can release VOCs, contributing to air pollution and health risks. Hot melts, by contrast, are non-volatile.

Source materials: Adhesives can be made from renewable, natural, or synthetic resources. But “renewable” doesn’t always mean better. For example:

-

Animal-based adhesives (like casein) are renewable but not always sustainable.

-

Plant-based starch adhesives (like those in water-activated tape) can be both renewable and highly eco-friendly.

-

Synthetic adhesives (like acrylic emulsions) can sometimes be more sustainable depending on the use case.

The takeaway: don’t assume “natural” = compostable or “synthetic” = harmful.

End-of-Life

Adhesives matter less on their own and more in how they impact the whole package.

When you compost or recycle a box, tiny amounts of adhesive usually don’t change the outcome. Compost certification standards even allow adhesives and inks because they make up such a small fraction of the material.

That said, adhesives can still cause challenges in recycling. Pressure-sensitive adhesives (like old stamp glue) used to break into tiny pieces during pulping, slipping through screens and contaminating recycled paper.

To solve this, Recycle Compatible Adhesives (RCAs) were developed. These adhesives stay intact through pulping so they can be screened out, preventing “stickies” and defects.

At EcoEnclose, nearly all of our packaging, labels, and stickers use RCA formulations, making them more recycling-friendly. This—more than compostability—is the eco characteristic we prioritize in adhesives.

Source: Unsplash

Common Adhesive Issues in Sustainable Packaging

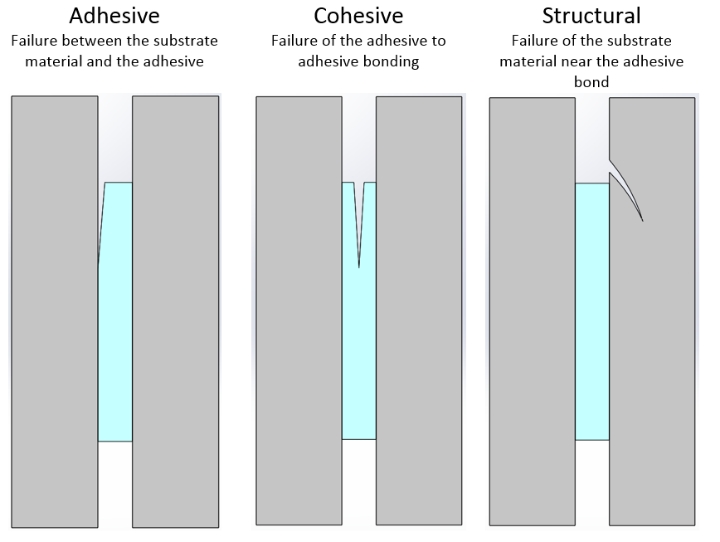

There are three main types of adhesive failure:

-

Adhesive failure – The glue doesn’t stick well to the surface. When pulled apart, the adhesive stays on one surface but not the other.

-

Cohesive failure – The glue itself breaks apart, leaving residue on both surfaces.

-

Substrate failure – The bond is stronger than the material. For example, pulling tape off a box rips some of the box onto the tape.

You may face some adhesive issues when working with 100% recycled (often 90%+ post-consumer) corrugate and paper.

If you do face this, it is largely driven by the characteristics of recycled paper.

Each time paper is recycled, its fibers become shorter. The shorter fibers of a recycled corrugated shipping box or a recycled mailer make it harder to form tight bonds with adhesives.

We have only come across this issue with pressure-sensitive adhesives, not hot melt or water-activated adhesives.

The primary way to address an adhesive failure on recycled paper or corrugated is to apply more pressure for 5-15 seconds when applying the label, self-seal, or sticker.

This added pressure creates a stronger and more interlocked bond (remember that there are molecular interactions that firm up the bond!).

Source: EcoEnclose

What's Next for EcoEnclose's Eco-Friendly Adhesives?

At EcoEnclose, we know there’s always room to improve—especially when it comes to adhesives.

Sustainability is our first focus. While most of our adhesives are low or no VOCs, our long-term goal is to eliminate VOCs and any toxins altogether. Our adhesives are also designed to work with recycling, but we’re continuing to learn how different formulations impact the recycling process and how to create cleaner, higher-value recycled paper.

Renewable adhesives are another common question we get. We already use renewable resources in our carton sealing tapes and corrugated sheets. But for mailers, labels, and stickers, renewable options are either not available, not effective, derived from animals, or made from resources we believe should be protected. That said, as new renewable technologies emerge, we’re committed to testing and exploring them.

For now, the most meaningful improvement opportunity lies in strengthening how our adhesives interact with recycled paper. Every month, we ship thousands of packages in our recycled boxes, mailers, labels, and stickers—and thanks to your feedback and our own experience, we’re continually working to make these adhesives stronger, smarter, and more sustainable.

Some EcoEnclose Adhesive Wins!

Our first mailers required lots of pressure to seal. Today, with a stronger adhesive and textured paperboard, the seal is quick, easy, and reliable. About 10% of our orders now ship in these improved mailers.

Early versions needed extra pressure to stick to recycled corrugate. We reformulated with a High Strength Corrugate adhesive—now they bond perfectly to recycled boxes and paper mailers.

Standard labels struggled on our fully recycled, uneven padded mailers. Our Hi-Tac labels solved this with hot-melt adhesive that creates a strong, lasting bond.

Head over to our Sustainable Packaging Resource Center to learn more about eco-friendly packaging, or peruse our blog for more on recycling, packaging, and more!

About EcoEnclose

EcoEnclose helps forward-thinking brands deliver on their sustainability goals with innovative, research-driven packaging solutions designed for circularity.