Poly Bags with Seal

Show off your products while keeping them safe. Our recycled clear poly bags are ideal for inner packaging, shielding contents from dust, moisture, and scratches. Made with recycled content and available with suffocation warnings to meet Amazon FBA and state regulations, our poly bags are protective, compliant, and better for the planet.

Recycled Content

Made with 100% pre-consumer recycled content. Also includes ink and adhesives.

Resealable

Features a resealable adhesive strip to reseal the bag easily.

Transparent

Made with clear plastic, allowing for easy barcode scanning and product visibility.

Thin Film Recyclable

Recyclable via source-separated thin-film streams at store drop-off locations.

Made in USA

Utilizes local recycled inputs, transparent supply chain, lower transportation footprint.

Custom Poly Bags

Create an exceptional customer experience with custom poly bags. Customization is available starting at 15,000-150,000 units. Work with us on unique projects, including custom dimensions, custom printing, wicketing and labeling, various mil thicknesses, and more.

| Material | Linear low-density Polyethylene (LLDPE) |

| Recycled Content | Functional plastic resin is 100% pre-consumer recycled content |

| Thickness | 1.5 mil |

| Material Features | Moisture, tear, tamper-resistant FDA-Compliant for direct food contact |

| Functionality | Self-seal adhesive closure Resealable adhesive strip for reuse |

| End-of-Life | Recyclable with thin film |

| Origin | Made in USA |

| Bag Color | Clear, printed with or without suffocation warning |

| Suffocation Warning | Meets Amazon FBA and state requirements. (English/Spanish/French) WARNING: To avoid danger of suffocation, keep this plastic bag away from babies and children. Do not use this bag in cribs, beds, carriages, or play pens. This bag is not a toy. Bag size 4 x 5", 6.25 x 8.25" = font size 10pt Bag size 8.25 x 10.25", 9.25 x 12.25", 11.25 x 14.25" = font size 12pt Bag size 12.25 x 18.25" = font size 14pt Bag size 18.25 x 24.25" = font size 18pt |

| Print Color | Pantone Color Matching System (PMS) |

| Ink Type | Solvent-Based Inks |

| Print Process | Flexographic |

| Print Option | Inline: custom dimensions, custom printing, wicketing and labeling, various mil thicknesses, and more - request quote |

What is the difference between poly bags, poly mailers, and plastic bags?

A poly mailer is a plastic envelope that ships durable and soft commodities. It is constructed from thin, lightweight, and sturdy polyethylene film that is waterproof and tamper-resistant.

A plastic bag is a general term covering traditional grocery bags, resealable bags, mailer bags, and more.

Are poly bags sustainable?

While poly bags can usually be taken to a designated drop-off location, we provide a take-back program where consumers without access to thin film recycling can return these bags to EcoEnclose.

We use LDPE (low-density polyethylene) instead of PVC, PP, or other types of plastic because it is more readily recyclable in the United States, more protective, and more sustainable overall. While it does have a slight opacity compared to polypropylene, its recyclability and stretchability make it a superior option.

Many people ask if we have degradable or biodegradable poly bags. We do not for a few key reasons. These plastics are often designed to degrade quickly, but like normal plastic, they cannot fully degrade. Instead, they quickly break down into microplastics. Other types will emit methane as they degrade, greatly contributing to greenhouse gas emissions.

As for bioplastics, they are typically made from virgin materials rather than recycled ones, and they can only be composted in an industrial facility. This makes them less sustainable than they at first seem.

Learn more about bioplastic and degradable and biodegradable plastics

What are the sizes, dimensions, and weights of EcoEnclose poly bags?

| SKU | Product Description | Parcel Weight (lbs) | Parcel Weight (oz) | Parcel Dims (in) | Bag Weight (lbs) | Bag Weight (oz) |

|---|---|---|---|---|---|---|

| FS4-200 | 4" x 5" - Bundle, 200 | 0.63 | 10.1 | 5 x 5 x 2 | 0.003 | 0.048 |

| FS4-1000 | 4" x 5" - Case, 1000 | 3.8 | 60.8 | 7 x 6 x 4.75 | 0.003 | 0.048 |

| FS6-200 | 6.25" x 8.25" - Bundle, 200 | 1.13 | 18.1 | 7.5 x 7 x 2 | 0.005 | 0.080 |

| FS6-1000 | 6.25" x 8.25" - Case, 1000 | 6.11 | 97.8 | 12.5 x 10 x 4.75 | 0.005 | 0.080 |

| FS7-200 | 7.25" x 10.25" - Bundle, 200 | 2 | 32 | 9 x 6 x 2 | 0.01 | 0.160 |

| FS7-1000 | 7.25" x 10.25" - Case, 1000 | 8.8 | 140.8 | 13 x 10 x 5 | 0.01 | 0.160 |

| FS9-200 | 9.25" x 12.25" - Bundle, 200 | 2.43 | 38.9 | 10.5 x 8.5 x 2 | 0.0125 | 0.200 |

| FS9-1000 | 9.25" x 12.25" - Case, 1000 | 15.29 | 201.4 | 18.5 x 13.5 x 4.75 | 0.0125 | 0.200 |

| FS11-200 | 11.25" x 14.25" - Bundle, 200 | 2.94 | 47.04 | 11 x 10 x 2 | 0.015 | 0.240 |

| FS11-1000 | 11.25" x 14.25" - Case, 1000 | 17.45 | 279.2 | 18.5 x 12.5 x 4.75 | 0.015 | 0.240 |

| FS12-200 | 12.25" x 18.25" - Bundle, 200 | 4.36 | 69.8 | 13.5 x 12.5 x 2 | 0.0225 | 0.340 |

| FS12-1000 | 12.25" x 18.25" - Case, 1000 | 22.93 | 366.9 | 20 x 14.5 x 4.75 | 0.0225 | 0.340 |

| FS18-200 | 18.25" x 24.25" - Bundle, 200 | 8.73 | 139.7 | 19.5 x 14.5 x 2 | 0.033 | 0.530 |

| FS18-1000 | 18.25" x 24.25" - Case, 1000 | 41.6 | 665.6 | 21 x 14.5 x 5 | 0.033 | 0.530 |

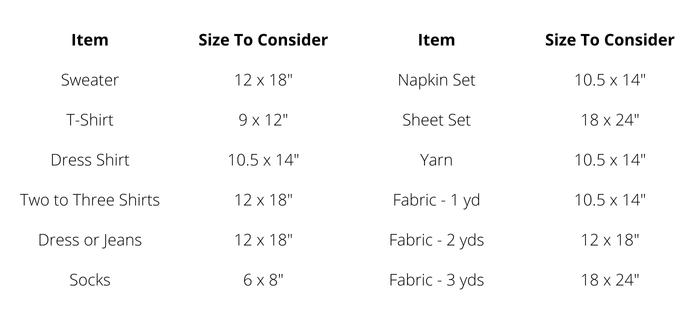

What size poly bag do I need?

Once you have what you think is the perfect-sized bag, order a free sample to test them. This way, you can be 100% sure you have the size you need before buying in bulk.

As a frame of reference, we’ve compiled a table of common products shipped in our bags.

Are EcoEnclose poly bags FDA-Compliant?

Learn more about gusseted bags, delivery to Asian factories, and more

- Gusseted poly bags—minimum order of around 25,000 units

- Delivery to Asian factories overseas

Suffocation Warning Legal Requirements

Learn what you need to know, what elements of your packaging strategy this may apply to, and what this means for using our poly bags.

Thin Film Recycling and How2Recycle Labeling

Navigate the nuance of thin film including thin film recycling, legislation and recycling certifications to consider, and How2Recycle Labeling.

Sustainable Alternatives to Clear Poly Bags

Our inner packaging solutions separate your goods and provide protection in transit. We offer paper inner bags for those who want to avoid plastic entirely.

Find a Thin Film Drop-Off Location

Reference How2Recycle's list to see nearby retailers who may have drop-off points available.