Points, Pounds, GSM: What Do You Need in Paper Packaging?

Posted By on Jul 27th 2023

Points, Pounds and GSM. What's the Difference?

Our lives are filled with paper. We learn to read and write on it. Half of what we buy is packaged in some form of it. Our mailboxes are stuffed with it.

But, the world of paper is more complex than you might think. As you make decisions about your business cards, hang tags, paper packaging, and brochures, you might realize that there’s a lot that you don’t know. Don’t worry; we’re here to help.

In this article, we’ll demystify the world of paper and go into detail about Basis Weight, Metric Weight, and thickness—three different but sometimes interchangeable ways to evaluate paper—as well as the difference between paper, paperboard, and corrugate. Let’s dive in!

Comparing paper weights and thicknesses

Paper stock is described in two ways: weight and thickness. While points typically describe the thickness of the paper, the paper weight can be measured in two ways: U.S. Basis Weight and Metric Weight (GSM).

While this all may seem pretty straightforward, unfortunately, it is not. Let’s take a closer look at these measurements.

Paper weight

As usual, the U.S. measures things differently than the rest of the world. Because of this, there are two different systems to measure the weight of paper.

U.S. Basis Weight (Bond, Book, Index, Cover, Tag, Points, Offset)

Raise your hand if you’ve often wondered why the U.S. doesn’t follow the straightforward metric system! In typical fashion, the US Basis Weight system is the most confusing of the paper measurements.

Here’s how it works: The “Basis Weight” is defined as the weight (in pounds) of 500 sheets of paper in its uncut size (before the paper is cut to letter size, legal size, etc.). For example, if you have 500 sheets of uncut bond paper that weighs 20 pounds, it will be labeled as 20-pound bond paper.

The confusing part is that the uncut sizes do not reflect the size of the paper in its final form. For example, bond paper—the most common type of paper around the office—is 17 x 22 inches in its uncut form. So, when it’s cut to letter size (8.5 x 11 inches), it will still be referred to as 20-pound bond paper even though a ream of letter-size bond paper is lighter than 20 pounds.

Another baffling aspect of this type of measurement is that there is no standard for uncut size. Therefore, you cannot compare the Basis Weight of different paper types. Take a look at this chart:

| Paper Type | Uncut Size | Available Weights | Common Uses |

| Bond paper | 17 x 22 inches | 16, 20, 24, 28, 32, and 36 pounds | Lighter weight for printers, copiers, letterheadHeavier weight for signs, flyers, contracts, and resumes |

| Book paper | 25 x 38 inches | 30 - 115 pounds | Books, booklets, magazines |

| Cover paper | 20 x 26 inches | 60 - 120 pounds | Business cards, menus, postcards |

| Text paper | 25 x 38 inches | 50, 60, 70, 80, and 100 pounds | Commercial printing of letterhead, thesis papers, internal memos, and brochures |

Because U.S. Basis Weight can be so confusing, the Metric Weight is often printed next to it to avoid uncertainty.

Metric Weight (GSM)

The metric system is more straightforward because it doesn’t differentiate by paper type or use.

Instead, grammage reflects the actual weight of one sheet of paper cut into a 1x1-meter square. Since the same size sheet is always being weighed, regardless of the characteristics of the paper, GSM (grams per square meter) is a clear and easy-to-digest way to evaluate paper weight and thickness.

Paper thickness

It’s important to note that the weight of the paper will not necessarily describe the thickness of the paper. That’s why knowing how paper thickness is measured is also important. (To add to the confusion, however, U.S. Basis Weight is sometimes used to describe thickness, so be aware of this as you make your paper decisions.)

Points

In the United States, paper thickness (sometimes called its caliper) is measured using points. Each point amounts to 1/1000-inch. Therefore, a piece of paper with a thickness of 0.012 inches is labeled 12-point paper.

The following table provides a basic comparison of some of the more common types of paper types, thicknesses, and weights.

Choosing the right paper for your needs

Still confused? Not to worry, even those within the printing and packaging industries sometimes get confused about the jargon surrounding paper. It’s neither simple nor straightforward; most of the time, you don’t need to have a deep understanding of paper measurements to fulfill your business needs.

Here are some basic things to know:

- Internal Kraft bags are made of 30-pound or 40-pound cover paper. This makes it thin but functional for the needs of inner packaging. Several of our packaging paper options are also in this same paperweight category.

- Paper mailers range drastically in thickness. Our Kraft Mailer is made with 10-point paperboard. Our EcoX Mailers are slightly thicker at 11 points, and our Paper Apparel Mailers are much thicker at 15 or 18 points, depending on the size. Finally, our rigid mailers are significantly thicker—up to 36 points thick. The wide range of thicknesses provides ample options for shipping apparel, posters, premium products, and more.

- Notecards, business cards, hang tags, and other marketing materials can range drastically in thickness, typically from 80 pounds to 130 pounds cover. We recommend an 80-pound cover in most instances. Because these materials don’t need to be sturdy for functional, protective reasons (the way packaging does), we encourage you to use as little material as possible. When 80 pounds isn’t substantial enough for your needs, opt for a 110-pound cover as the next best alternative.

Paper versus paperboard versus corrugate

Paper-based packaging is generally made with either paper, paperboard, or corrugate. But what’s the difference? Briefly, corrugate is stronger than paperboard, which is stronger than paper. Let’s take a closer look.

Paper

There isn’t a technical and perfect delineation between paper and paperboard. But we’re going to attempt one, anyway.

Paper is typically used to describe thinner, less sturdy material than paperboard. Paper categories include Bond, Text, Cover, Book, and Index. Paper should be used to package lightweight items, like apparel or textiles.

Our 100% Recycled Kraft Mailers and our various packaging paper options are all made with paper of varying thicknesses and weights. Our 100% Recycled Padded Mailer is made with two layers of kraft paper with a layer of shredded recycled paper sandwiched inside.

Paperboard

The term paperboard is generally used to describe stronger, stiffer paper-based material that is 12 points or more thick. Paperboard is used to produce a variety of different types of packages, such as cereal boxes. When paperboard is made with 100% recycled material, it is often called “chipboard” or “bending chip.”

Our 100% Recycled Retail Boxes, 100% Recycled Rigid Mailers, and 100% Recycled Apparel Mailers are all made with paperboard. These are ideal for packaging art prints, documents, mid-weight apparel, or premium products.

Corrugate

Corrugate (sometimes referred to as “cardboard,” though this isn’t entirely accurate) is what shipping boxes are made out of. Corrugate consists of two layers of liner board (kraft paper that is usually around 10 points) with a layer of fluted kraft paper in the middle. This dual layer allows corrugate to have a significantly lower cost and use less material than a paperboard of equivalent strength would be. Additionally, corrugate is the most readily and easily recyclable paper-based packaging, securing the highest market pricing from reclaimers. This is partly because shipping boxes are likely mostly free of contaminants such as staples, ink, and residue.

The actual flutes in corrugate vary across two main characteristics – their height (which creates the thickness of the cardboard sheet) and how tightly or loosely they are waved or “fluted.” The following chart describes the most common types of flutes used in shipping:

The following chart describes the most common types of flutes used in shipping:

| Flute | Characteristics | Good For | |

| B Flute | 1/8” thick, 42-50 flutes per foot | Resisting crushing, stacking strength. Good for folding and printing, and therefore, good for presentation style boxes such as Tab Locking and Literature Mailers. Lower price vs C or E flute. | |

| C Flute | 11/64″ thick, 39-43 flutes per foot | Provides good cushioning and strong enough for medium weight boxes. An effective surface for printing (though slightly less so than B flute). | |

| E Flute | 1/16” thick, 90-94 flutes per foot | Strong crush resistance. Excellent surface for printing. Excellent for folding. Becoming more popular in ecommerce presentation boxes. Reduces box storage space. |

The above chart describes “single-wall” boards. Corrugated sheets can also be double- or triple-wall for added thickness and strength. Double and triple-wall corrugated flutes are described by the flutes of the two or three sheets used together. Multi-wall corrugate is typically only used in larger industrial containers and is rarely used in traditional e-commerce. Most e-commerce shipping boxes are made with single-wall B, C, or E flutes. These strike an appropriate balance of creating strong boxes that are relatively lightweight.

Our 100% Recycled Shipping Boxes are corrugated, as are our Corrugated Bubble and Corrugated Pads. Use these when shipping larger items or orders with multiple items.

How should I compare all of my paper packaging options?

With so many paper options, it’s easy to feel overwhelmed. That’s why we’ve worked hard to cultivate an informed shopping experience so you can feel secure in your order. Our packaging options come with thorough descriptions and suggestions for which products are ideal to be shipped in them.

When choosing your paper packaging, you must find that spot between durability and conservation. Opting for eco-friendly packaging is about reducing waste, and you don’t want to choose paper packaging that uses more material than you might need. However, you still want to ensure your products arrive at your customers’ doorsteps safely and securely.

That’s why we offer free samples to our customers. Especially when it comes to paper and its confusing sizing, you might want to see and feel each packaging option before you choose the best ones for your products. Check out our samplings here.

Our paper packaging recommendations

If you’re looking at mailers to ship your goods:

Kraft Mailers

Lightweight paperboard and affordable price point. Ideal for shipping flat, lightweight, and non-fragile items that can be bent. 100% recycled, 90% post-consumer waste.

Available in 7 sizes

Ready to ship | Min. 25 units

Customizable | Min. 500 units

Apparel Mailers

Creasing for expandability and premium presentation. Ideal for shipping bulkier apparel and gear, and soft goods. 100% recycled, 97% post-consumer waste.

Available in 4 sizes

Ready to ship | Min. 25 units

Customizable | Min. 500 units

Padded Mailers

Upcycled newspaper sandwiched between recycled Kraft paper. Extra cushioning make them ideal for shipping fragile items. 100% recycled, 20% post-consumer waste.

Available in 5 sizes

Ready to ship | Min. 10 units

Customizable | Min. 500 units

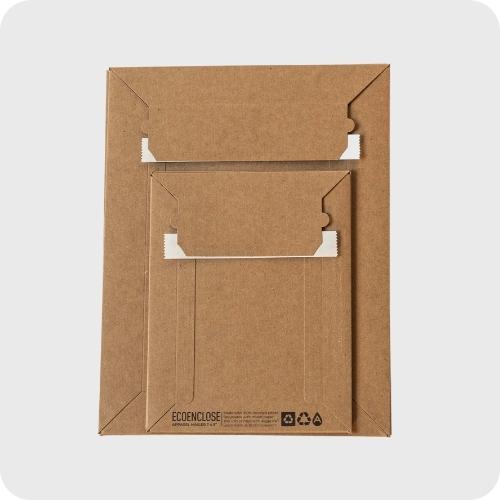

Self-Seal Rigid Mailers

Thick 28pt paperboard for a sturdy construction. Ideal for shipping art prints and photos, and other items that should not be bent. 100% recycled, 90% post-consumer waste.

Available in 3 sizes

Ready to ship | Min. 10 units

Customizable | Min. 500 units

If you’re unsure about shipping boxes or mailers:

Shipping boxes are typically more expensive, space-intensive, and require assembly, which adds to your operations. Although we recommend choosing mailers when possible, shipping boxes work particularly well for:

- Bulky items or products with a height, depth, and length over 2 inches

- Companies shipping multiple products at a time

- Monthly subscription services

- Fragile items

- Companies focused on exceptional presentation and branding

- Oddly shaped items

To help you choose which box is best for your business, check out our Ultimate Guide to Custom Shipping Boxes.

Don’t forget! All of our mailers and shipping boxes can be custom branded.

Still not sure how to move forward? We'd love to help! Contact us.