Pressure-Sensitive Tape

Recommended for low-volume applications, pressure-sensitive tape consists of film and a tacky substance that adheres to a surface with light pressure. Available in paper and plastic.

Recycle Compatible

Not recyclable, but it does not inhibit the substrate from being recycled.

Renewable

Made from readily renewable raw materials that can be regrown.

Compostable

Our cello tape is compostable in industrial composting facilities.

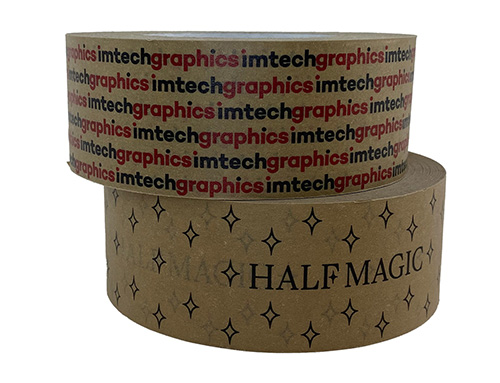

Custom Packing Tape

Create an exceptional customer experience with custom packing tape. Add your unique branding starting at just 60 units. Printed with HydroSoy ink, our pressure-sensitive tape can be branded in two colors.

Start DesigningRead Artwork Guidelines

Do you ship 1,000+ orders per week? Work with us on unique projects.

Start Your Order