The World's Most Sustainable Ink

Updated June 27, 2022

The Future of Ink is Algae Ink™

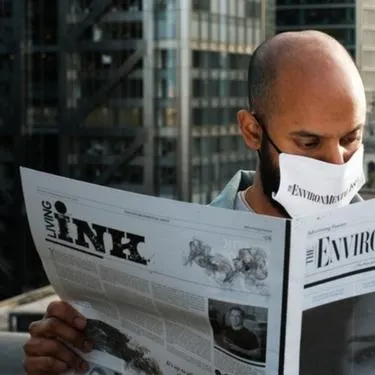

Black ink is on almost everything. Unfortunately, most black pigment is made with carbon black pigment generated from fossil fuels. Algae Ink™ is here to change this standard. It is a revolutionary ink developed by Living Ink Technologies that uses algae cells for pigments, making it safer and cleaner to work with and more compatible with recycling and composting. Algae Ink™ incorporates a net negative carbon technology; the process to make its Algae Black™ pigment sequesters more carbon than is emitted.

Today, Algae Ink™ can replace standard carbon black ink across various applications and industries. Read on to see how Algae Ink™ changes the future of packaging, apparel, and durable goods.

Shipping Boxes

Water-Activated Tape

Paper Mailers

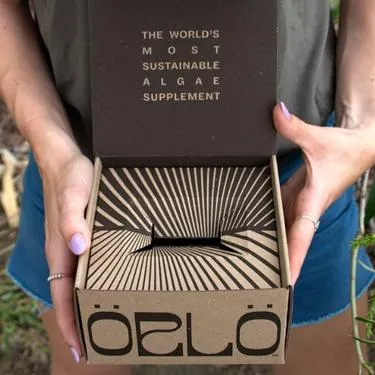

Retail Packaging

Glassine Bags

Hang Tags

Stamp Ink

Notebooks & Brochures

Tissue Paper

Notecards & Business Cards

Sway Polybags

What Our Customers Are Saying

I like to reduce our carbon footprint any way I can. The simple kraft box with Algae Ink™ provides a modern look of classy environmental consciousness to our product packaging.

- UFlyMike

The Algae Ink™ print you all do on our 100% recycled boxes really makes our packaging shine at local and national retailers. Thanks for the awesome product and service, we continue to recommend Eco Enclose to all in our business network … awesome service as always.

- Bedrock Sandals

Globally, the Wurth Group, our parent company, has a major focus of sustainability and eco-friendly solutions. To be able to offer Algae Ink™ ... positively supports and drives our global initiative to do better for the planet. We LOVE this sustainable solution is available in the US.

- Wurth Elektroniks

Get In Touch

Algae Ink™ is a must-have for your products and packaging if you're building a sustainable brand. By incorporating this technology into your business, you are not only actively sequestering carbon, but also paving the way for this ink to become more mainstream and widely available long-term, which would be a significant win for the environment.

Contact us today to see how Algae Ink™ can set your brand apart.

Recent Wins in the World of Algae Ink™

Eltee Swim becomes the first-ever brand to print their poly mailers with Algae Ink™.

Frequently Asked Questions

For more in-depth information about the history of Algae Ink™ and why it is such a tremendous leap forward even when compared to standard water and soy-based inks, check out our post - How Algae Ink™ is Changing the Print Industry.

What makes Algae Ink™ sustainable?

Algae Ink™ is a bio-based and renewable ink made by mixing carbon-negative pigment Algae Black™ into a water-based or vegetable-based carrier. This pigment sequesters more carbon than is used in its production, trapping it in a stable and inert form for hundreds of years. Every kg of Algae Black™ pigment produced keeps ~3 kgs of petroleum (crude oil) from being used. Additionally, because the pigment is carbon negative, 1 kilogram of Algae Black™ can remove -4 kilograms of carbon dioxide.

Algae Ink™ has more biorenewable content than any other ink on the market. Offset Algae Ink™ has 83% biorenewable content, and Flexographic Algae Ink™ has 90% biorenewable content.

What is carbon black? What is Algae Black™?

Carbon black is a pigment used in the ink, textiles, plastics, and rubber industries. It is derived from the mining and burning heavy petroleum, such as FCC tar, coal tar, or ethylene cracking tar. According to the International Agency for Research on Cancer (IARC), it is a class 2 b carcinogen. Thus, carbon black is hazardous to human health, causes environmental degradation, and is produced using finite resources.

Algae Black™ is a bio-based, renewable, and safe carbon black alternative. Algae biomass waste leftover from farms is diverted from landfills and transformed into tiny black pigments in a dry powder form. These powder pigment particles are then blended into water-based or soy-based ink formulations to create Algae Ink™ printing inks that we use at EcoEnclose. [Source: Living Ink Technologies]

Where can Algae Black™ and Algae Ink™ be used?

Technically, Algae Black™ pigment can be a replacement whenever carbon black pigment is used. As of 2024, Algae Black™ pigment is actively used in the ink formulations of Flexographic Algae Ink™, Offset Algae Ink™, and Screen Algae Ink™. Living Ink Technologies has also developed formulations for cosmetics, textiles, footwear, and dyes in plastics.

Unfortunately, inks colored with Algae Black™ are currently unavailable for digital printing applications (toner or inkjet). Please reach out if you have a new idea for how your company wants to use Algae Ink™.

Why is Algae Ink™ more sustainable than soy or water-based inks?

Soy and water-based describe the ink's "carrier" (the agent that carries pigment onto the printing substrate). The move from solvent carriers to water- and plant-based carriers was great for the environment, but the conventional pigments in these inks are still derived from fossil fuels.

Algae Ink™ is a leap forward in the landscape of sustainable inks, as its pigment (Algae Black™) is biorenewable and derived from algae (algae waste generated by an algae farm from its nutritional supplement production). In addition to this safe, waste stream pigment, Algae Ink™ utilizes water or plant-based carriers, making it the most renewable ink available today.

Are my volumes too high to use Algae Ink™? Or too low?

Is Algae Ink™ only available for shipping packaging?

Is Algae Ink™ recyclable?

Is Algae Ink™ compostable?

As composting becomes more common, we believe people must consider the impact of the small components of their packages, such as inks and adhesives. We are so excited about Algae Ink™ because its Algae Black™ pigment (primarily left on the package) is biorenewable, natural, and, therefore, safer for our soils.

Will Algae Ink™ fade over time?

Is Algae Ink™ available in colors besides black?

Is Algae Ink™ more expensive than regular (fossil-fuel-derived) black ink?