Protective Packaging & Void Fillers

Ensure your packages arrive safely and with an eco-friendly unboxing experience.

Deliver every order safely and ensure sustainability in every detail. EcoEnclose offers a full range of packaging protection and void fillers, all designed to meet your shipping needs. Ship responsibly without compromising your commitment to the planet.

Tissue Paper

FSC® Certified paper protects against scuffing and dust. Brand with your unique design. 100% recycled, 20% post-consumer waste.

Available in 1 size and 2 colors

Ready to ship | Min. 480 units

Customizable | Min. 4,800 units

Packing Paper

Provides bracing in a shipping box and light protection when wrapped around products. 100% recycled, 30% post-consumer waste.

Available in 2 types

Ready to ship | Min. 1 unit

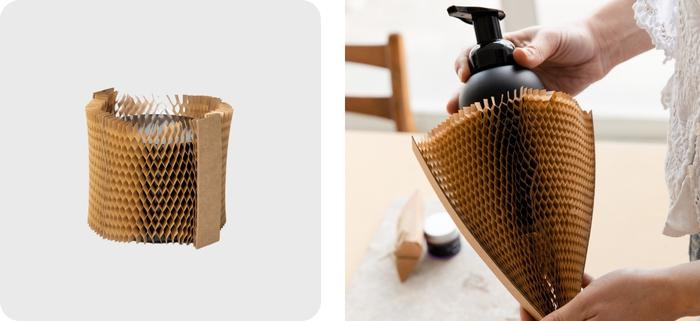

GreenWrap

Die-cut honeycomb paper ships flat and expands to create moldable cushioning. Made with certified, virgin paper.

Available in 1 size and 2 colors

Ready to ship | Min. 1 unit

Flexi-Hex Sleeve

Lightweight, flexible honeycomb sleeves ship flat and expand to wrap around fragile items. 100% post-industrial waste.

Available in 4 sizes and 2 strengths

Ready to ship | Min. 100 units

Slivv Paper Transport Sleeve

Corrugated shock-absorbing paper sleeves ship flat and open to wrap around fragile items. 100% recycled, 100% post-consumer waste.

Available in 3 sizes

Ready to ship | Min. 100 units

SpiroPack Nest Eco

Spiral tissue paper void fill quickly creates sustainable volume. The continuous design makes fulfillment a breeze. 95-100% recycled.

Available in 2 colors

Ready to ship | Min. 10 lbs

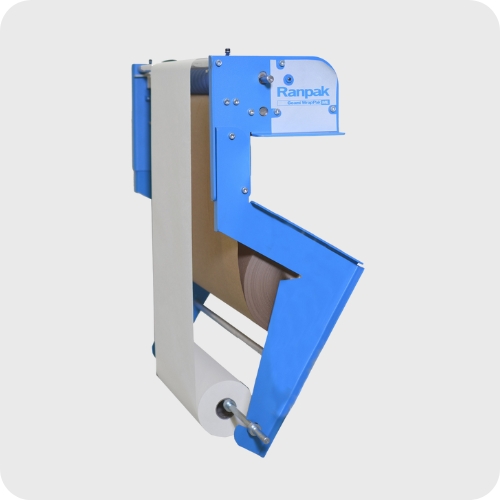

Automated Void Fill

Automated dispensers for GreenWrap and packaging paper. Ideal for high-volume fulfillment.

Available in various styles

Min. varies | Request a quote

Frequently Asked Questions

Protective Packaging. Void fill. Cushioning. We use these terms to refer to any cushioning, padding, or paper you add to your shipping package to protect your goods in transit and create a beautiful presentation for recipients. There are many different types of void fill and packaging fillers out there, each unique in functionality, aesthetic, sustainability and cost.

Packing material is more than just shipping box stuffing. While void fill or box filler is largely a solution used in corrugated shipping boxes, it is also becoming more common in mailers, largely to add a little "wow" factor to the presentation.

Consider the following questions.

- Are my products fragile?

- Are my products very heavy?

- Are my products corners subject to damage?

- Does my package have significant excess space that could cause my products to move around and bend, damaged, or scuffed while in transit?

- Is it important to me and my brand that my customers receive a package that is unique and enjoyable to open?

If you answered yes to any of the above questions, void fill should likely be part of your packaging strategy. Corrugated shipping boxes are the most likely shipping strategy to require void fill of some sort because they are the most likely to contain excess air. But there are certainly cases where void fill is not needed.

For example, EcoEnclose customers that sell hats, shirts, handbags, or items that are already packaged in a retail style box can order custom shipping boxes that fit their specific products well enough that there is minimal excess air or fear of product movement. This eliminates the need for packaging fillers.

Mailers do not typically require void fill, though many companies look to wrap their products for the sake of presentation. If a company is packaging something like essential oils or perfumes in a mailer, they may decide to wrap their products in protective cushioning or void fill before placing those goods in the shipping mailer.

If you’ve decided to explore protective packaging for your packaging solutions, the next step is to be clear on which of the following purposes your protective packaging will serve so you can find the right solution. Typically, your need for protective packaging will fall into one or more of the five following categories:

INDIVIDUAL PRODUCT PROTECTION

Wrap each product with cushioning for protection against the impact of a dropped package and from product-to-product collision. Items like glassware, bottles, candles and pottery need this type of protective packaging.

Recommendation: SpiroPack Nest Eco, Flexi-Hex Air Sleeve

VOID FILL

Having a streamlined set of shipping boxes that can accommodate orders varying in product set and quantity. These boxes end up with empty space that need to be filled with cushioning for blocking and bracing so items don’t move and damage themselves or each other in transit.

Recommendation: SpiroPack Nest Eco, Packing Paper

CUSHIONING

Some items, such as books, are not fragile or awkwardly shaped but often require edge crush protection to ensure that impact to the package does not result in the crushing of corners and sides.

Recommendation: SpiroPack Nest Eco

DUST & SCUFF PROTECTION

Some items, such as apparel or textiles shipped in a corrugated box, are not fragile or prone to breakage. However, they may call for basic dust and scuff protection.

Recommendation: Tissue Paper

PRESENTATION

Presentation adds a unique finishing touch to your product packaging to leave customers with a beautiful and lasting impression and showcase your brand. Some items that serve the previously described functional needs of void fill can also be used in such a way that they enhance your package presentation.

Recommendation: Tissue Paper

Packaging Paper

Packaging filler paper is used to fill space and offer full product protection, corner and edge protection, and presentation.

If you’re aiming to fill space, crinkle or ball the packaging paper up and place it in your box after you’ve added your products. If you’re looking to protect products, wrap individual products in sustainable packaging paper, add these to your shipping package, and then - if needed - add balled-up packaging paper to fill in empty spaces. If you’re looking to enhance the presentation of your products, wrap your items up with packaging paper (like you would a decorative wrapping paper) and consider using hemp twine or a sticker as a finishing touch.

All EcoEnclose packaging paper filler is recyclable and compostable. EcoEnclose offers packaging paper that is made with 100% recycled material and is available on a roll (with dispensers also available for easy parsing and tearing so you use only the amount of material you need). We have multiple options that each vary in thickness, cushioning and price.

It may be tempting to just order the least expensive option of stuffing paper for shipping, especially because in pictures, they all look pretty similar. But we encourage you to think through what you need - how much protection, how much space to fill, etc. In many instances, you’ll find that with the thicker or the indented paper you can get adequate protection with significantly less paper, making these thicker packaging paper options more cost-effective and more sustainable in the long run. If, on the other hand, you’re interested in wrapping each product with paper, a thinner, more pliable option might work best.

Kraft Paper: This the “everyday Jane” of paper packaging filler, and is the type you are probably used to seeing in online orders you receive at home. It's a brown kraft paper that is versatile and effective. We offer three different types of kraft packaging paper. While all of our kraft packaging paper is the same price, you’ll see that they vary in length, with the thinner, lighter-weight papers having more square footage per roll than the thicker, sturdier ones.

30# Kraft Paper: The thinnest option we carry at EcoEnclose. A roll has 1200’. Our 30# kraft paper is thin and very pliable. It is a good option if you are just trying to fill a little bit of excess air in a package to hold a product in place. Because of its pliability, it is also a great protective option if you are trying to wrap a somewhat oddly shaped item (and need to wrap the packaging paper around the shape).

40# Kraft Paper: This is the industry standard thickness and weight for void fill. A roll has 900’. If you crumple it in a ball, it doesn’t “give” as much as 30# so even though it is slightly more expensive than 30#, it is ultimately a more cost-effective and sustainable solution when you’re trying to fill a moderate amount of excess air in a package because you can use less to hold an item in place. It also works well for wrapping items and is a better solution than 30# if you want to ensure sturdiness and strength to your product wrapping.

Indented Kraft Paper: This paper has ridges and bumps that add texture and a small amount of cushioning. If you just need a bit of protection and want to avoid the eco sadness of bubble wrap and the slight operational complexity of GreenWrap, this is a great option for wrapping products. It makes for a sleek and aesthetically pleasing final presentation. Indented paper offers more protection than flat packaging paper. This has 360’ per roll.

GreenWrap

Individual Product Protection

What It Is: A plastic-free alternative to bubble wrap. Die cut honeycomb paper that ships flat and is expanded through a dispenser. GreenWrap has two layers, a white tissue paper/liner layer and an outer layer that comes in a brown or white option. The dispenser (which is built into the box the GreenWrap ships in) is used to expand the outer layer of the GreenWrap, to create cushioning that can be molded around products for protection and presentation.

Eco-Features: certified sustainably sourced virgin paper, curbside recyclable, and naturally biodegradable.

Great For: Glass bottles, pottery, art pieces, candles, glassware, books that may be subject to edge crush concerns, and more. GreenWrap works well for companies who sell a variety of fragile goods, all of which are differently sized, that need individual wrapping and protection.

- Create a ball: Stretch the GreenWrap and crumple it up to make a nest to use as cushioning under your product.

- Wrap your products: Wrap your fragile products in GreenWrap before placing them inside your box.

- Line your box: Create a cushion and use it as a soft pad to line the bottom or top of your box.

- Watch & Learn: For more detailed instructions, check out the Void Fill and Green Wrap section of our video tutorials page.

Did You Know? If your company goes through 20+ cases of GreenWrap each year, consider a refillable dispenser.

Tissue Paper

Dust & Scuff Protection

What It Is: Lightweight paper that is slightly translucent and extremely pliable. Because decorative tissue paper is lightly calendared, it does not contain the “fuzz” that some types of paper give off, making it a great internal wrapping solution to protect items from dust and scuffs while providing a beautiful presentation. All of our tissue has a neutral pH, making it anti-tarnish and safe for silverware, jewelry, photographs, and more. Available in reams of 480 sheets in 20x30" sheet sizes.

Eco-Features: 100% recycled, either curbside recyclable or compostable (depending on the municipality), and naturally biodegradable.

Great For: Wrapping books, frames, apparel, soap, jewelry, accessories, and more. Recommended for products that don’t need damage or edge crush protection, but for those that need protection from dust and list scuffing. Many companies use tissue paper to wrap their products before placing them into their boxes or bags.

Flexi-Hex Air Sleeve

Individual Product Protection

What It Is: A plastic-free alternative to bubble wrap. Flexi-Hex Air Sleeves are lightweight honeycomb sleeves that ship flat and expand to be wrapped around fragile items. The innovative hexagonal cell structure not only provides incredible strength to protect fragile products in transit, but it also creates a sleeve that is extremely flexible. Compact to store and lightweight for economical shipping, when fitted around an object the sleeve expands open and takes on the form of the product within. It is packaging that looks delicate but is simultaneously strong.

Eco-Features: Certified sustainably sourced paper, made with at least 76% recycled content, curbside recyclable, and naturally biodegradable.

Great For: Glass bottles, candles, glassware, dishware, and more. Flexi-Hex is a great solution for companies that sell consistently sized items that each need individual wrapping and protection. Flexi-Hex is more operationally efficient than GreenWrap; however, the existing sizes must work for your business. Additionally, it does not provide top and bottom product protection, so consider adding one of the below cushioning or void fill options.

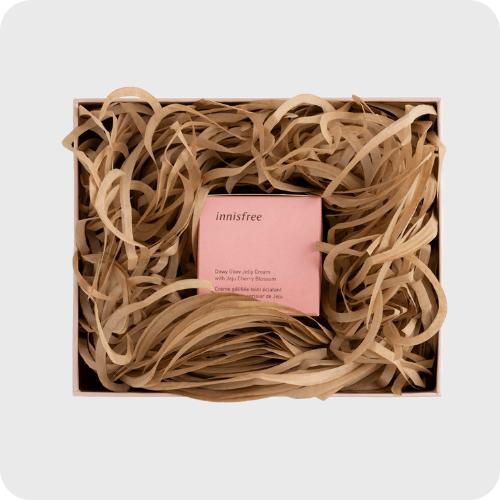

SpiroPack™ Nest Eco

Cushioning

What It Is: a unique and sustainable alternative to traditional crinkle fill and packing peanuts. SpiroPack’s patented flat design takes up 80% less space on your packing station than crinkle shred. The connected spiral design allows for easy packing during fulfillment and easy cleanup for consumers during unboxing.

Efficient packaging doesn’t need to be boring. Using SpiroPack Nest Eco is a quick and easy way to add volume to your package. Simply lift your desired amount of spirals by the tail, lift, shake to add volume, and put the fluffed SpiroPack Nest Eco into your eCommerce box.

Eco-Features: Certified sustainably sourced paper, made with 95-100% recycled content, curbside recyclable, and naturally biodegradable.

Great For: Companies that ship a variety of items in small boxes and need to lay down a cushioning and decorative nest at the bottom. While SpiroPack Nest Eco provides cushioning and protection and, it is more decorative and aesthetically pleasing. Because of this, it is typically paired with presentation-style boxes, such as Literature Mailers and Tab Locking boxes.

Slivv Paper Transport Sleeve

Individual Product Protection

What It Is: A 100% recycled paper sleeves that provides a renewable protective alternative to plastic bubble wrap. Slivv’s unique corrugated shock-absorbing design allows for flat storage and easy packaging. Additionally, Slivv features a bottom closure to keep your wine or other fragile items in place during transit.

Eco-Features: Made with100% recycled content, 100% post-consumer waste, reusable, curbside recyclable, and naturally biodegradable.

Great For: Shipping bottles and other fragile, long items.

Crinkle Paper

Crinkle paper is exactly what it sounds like, shreds of paper that are crinkled up like an accordion. It is used to fill boxes, cushion products and hold them in place, and make for a beautiful presentation.

The main downside is that it can be a little bit messy and cumbersome (with little strands of crinkle paper falling out every time you grab a fistful), both to use and for recipients to discard. Additionally, crinkle paper can be expensive – its base cost, and the cost of shipping the product to your warehouse – so it can be cost-prohibitive for some.

Our SpiroPack Nest Eco spiral tissue paper is an excellent alternative to crinkle paper because its connected spiral design allows for easy packing during fulfillment and easy cleanup for consumers during unboxing.

Peanuts

Loose-fill peanuts are those “S” shaped pieces made with expanded polystyrene (what you get when you inject plastic with air) that can be dumped into a box to fill in all of the excess air. They are easy for shippers to use, and offer good product protection.

While they do offer effective protection, they also have some important downsides. Peanuts are annoying for recipients as they are difficult to clean up and often cling to things and people. They are not aesthetically pleasing and make for a very underwhelming unboxing experience for recipients. And, they are very costly and unsustainable to ship – unlike many other void fill options that are stored in “compact form”. This also means they require lots of room to store.

Most importantly, they come with major environmental challenges. Recycled content options are available (though not with any post-consumer waste); however, they are extremely difficult to recycle. You have to find a specifically designed “difficult-to-recycle” facility for them, a step the vast majority of consumers will not make.

Bubble Wrap

Here’s a little bit of a fun fact - Alfred Fielding and Marc Chavannes invented bubble wrap when they found a way to seal pockets of air in between two plastic shower curtains to create a three-dimensional pattern of tiny bubbles that they had hoped would become a new wallpaper!

Bubble wrap has a lot of benefits for fragile items – it's moldable, offers great protection, and let’s face it – is super fun to stomp on and pop when you’re done. There are bubble wrap options with a sticky side to them, so they can easily wrap around a product and stick to itself without needing tape.

There are some pretty major downsides though. Thus far, bubble wrap is not available with much - if any - recycled content. Bubble wrap can be recycled, but a recipient would rarely know they can recycle their bubble wrap at grocery store drop-offs. If you happen to be using bubble wrap, be sure to encourage your customers to bring their bubble wrap with them when recycling all of their plastic bags at drop-off locations. And finally, like peanuts, bubble wrap is typically not stored in compacted form so it is expensive to get it delivered to you and takes a lot of room to store.

Inflatables

These small plastic pillows of air are becoming more common and can be used for void fill or blocking and bracing. They have their advantages. You can fill in spaces in boxes quickly and easily, with fairly minimal material. They are stored uninflated and flat.

Inflatables don’t, however, make for a good presentation. They often encourage companies to become lax about their box sizes and the amount of space between their products and their shipping boxes – which leads to more expensive, less eco-friendly shipping and customers who become frustrated with what appear to be wasteful practices. They also only make sense if you have an expensive “air filler” machine, so this is only feasible for companies of a certain size. And, once you buy a machine, you are committed to a single supplier for your inputs.

Finally, inflatables are certainly not a sustainability superstar, even beyond the fact that they encourage the use of excessive, wasteful boxes and the shipping of large amounts of air. While they are becoming available with some amount of post-industrial recycled content and can be found in biodegradable and grocery-drop-off recyclable options, the majority of them are still made with virgin poly and are not recycled.

Custom Designed Box Inserts - A Void Fill Alternative

If you’ve come this far you may be wondering - is there anything else besides these traditional packing filler and presentation options I can consider for my company? If you sell a standard product set (i.e. you typically sell four soaps at a time or have a package of five small perfumes that is very popular), you might consider a custom-designed box insert. This is a great option for lightweight, moderately fragile items (a simple bubble mailer is another option for these types of items).

Molded Pulp

Molded pulp is an eco-friendly alternative to polystyrene packaging solutions. Molded pulp trays can be designed to allow for multiple bottle or item sizes to be mixed and matched to work for your business. They can be made with 100% recycled materials and there is potential to use next-gen recovered materials such as agricultural waste. Often times, they are curbside recyclable and naturally biodegradable.

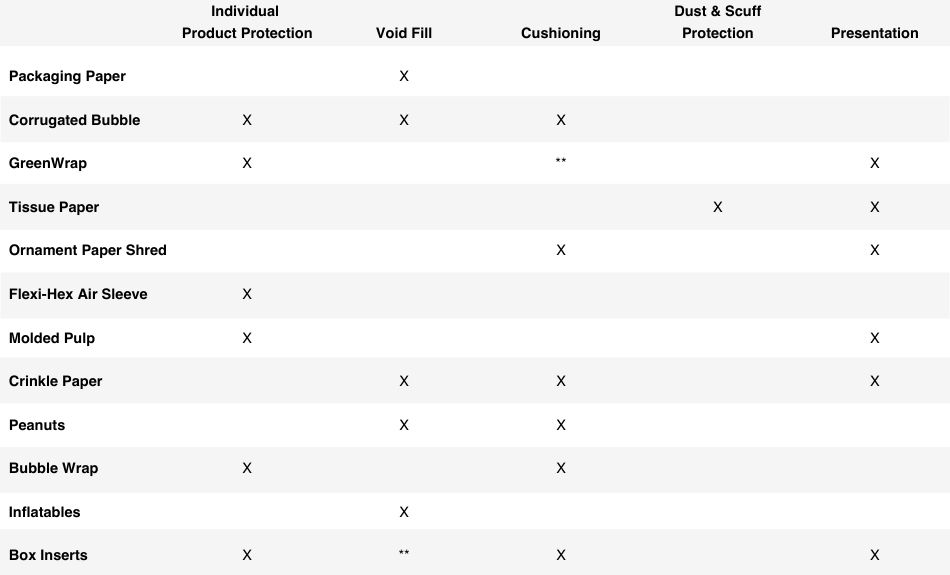

The following table summarizes how different traditional and eco-friendly void fill and box filler options could be used, and what functional needs they can meet, depending on how they are utilized.

**Can be used for this but not recommended to be used solely for this purpose