Packaging for Apparel

Eco-Friendly Packaging for Clothing

Let style meet sustainability with EcoEnclose.

Whether you're shipping T-shirts, pants, or outerwear, we offer eco-friendly clothing packaging that protects your products while delivering a memorable unboxing experience. Even better? Everything is customizable, so you never have to choose between sustainability and staying on-brand.

Explore our sustainable clothing packaging solutions today—each one designed for circularity and made to meet the practical needs of modern apparel shipping.

Table of Contents

Shipping Solutions for Apparel

Clothes do not break in transit, so apparel companies have the option to use more durable shipping boxes or flexible mailer bags. Both are great options, depending on your business. However, each has their pros and cons.

Mailers or mailer bags are often referred to as a shipping envelope or flat mailer. These shipping solutions are preconstructed envelopes that typically contain a self-sealing strip. Mailers are more cost-effective, efficient, and sustainable than shipping boxes because they use less material than an equivalent shipper box. They also take up less room than shipping boxes which makes storing them easier.

Shipping Boxes make for an exceptional presentation and work well for companies that want to go the extra mile for a unique, premium customer experience. While they are not as sustainable as equivalently sized mailers, our custom shipping boxes are 100% recycled, recyclable, and highly likely to be recycled. They work particularly well if your orders typically include three or more items.

Read more on our blog: Choosing Between a Mailer or a Shipping Box

Comparing Packaging Bags, Mailers, and Shipping Boxes

Apparel Mailers

THE GOOD

- 100% recycled, renewable source material

- Plastic-free (trace polymers in adhesives)

- 15pt paperboard - strong for bulky goods

- Gusset size made with 18pt paperboard

- Crease lines for expandability

- Curbside recyclable

- Naturally biodegradable and compostable

THE BAD

- More expensive than Kraft and Poly Mailer

- Heaviest mailer - more expensive to ship

- Strong seal requires firm adesive pressure

- Paper can tear or puncture

- Paper is not 100% weather proof

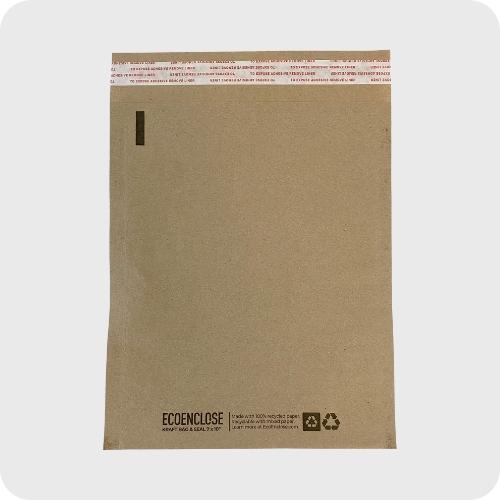

EcoX Mailers

THE GOOD

- 100% recycled, renewable source material

- Plastic-free (trace polymers in adhesives)

- Extremely durable, strong fibers

- Water resistant

- Curbside recyclable

- Naturally biodegradable, compostable

THE BAD

- More expensive than Kraft Mailer

- Less presentable than Apparel Mailer

- Paper can tear or puncture

Kraft Mailers

THE GOOD

- 100% recycled, renewable source material

- Plastic-free (trace polymers in adhesives)

- Lower cost than Apparel Mailer

- Made with 10pt paperboard - lightweight

- Two sizes feature side gusset

- Curbside recyclable

- Naturally biodegradable, compostable

THE BAD

- 10pt paperboard - less protective

- Paper is not 100% weather proof

- Paper can tear or puncture

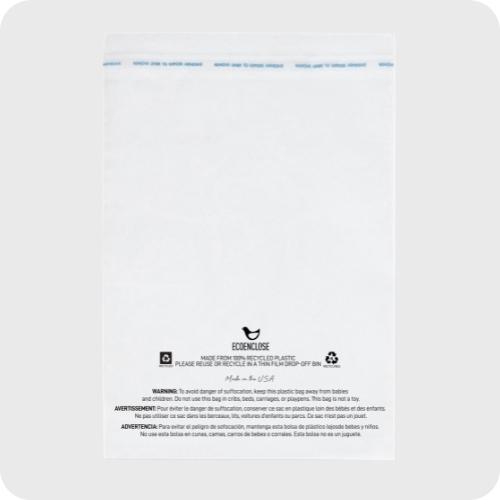

Poly Mailers

THE GOOD

- Lowest cost

- Weather-proof

- Reusable for returns

- 100% recycled

- Lightest option

- Lowest carbon footprint

- Recyclable

THE BAD

- Has to be recycled in plastic film-specific bin

- Loses its shape if product does not fill it out completely

- Flimsier presentation

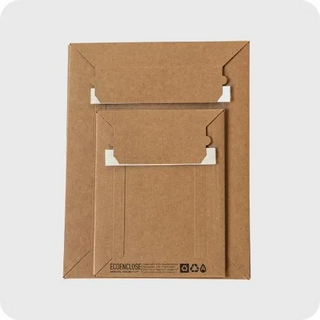

Custom Shipping Boxes

THE GOOD

- Naturally biodegradable, compostable

- 100% recycled, renewable source material

- Strongest, most durable and protective option

- Excellent presentation

- Custom cut by EcoEnclose for a perfect product fit

- Lightest option

- Curbside recyclable

- Naturally biodegradable, compostable

THE BAD

- More expensive than mailers

- Heaviest solution - higher inbound and shipping costs

- Typically increase the amount of air that is shipped

- Requires assembly and tape

- Bulkier to store

- Highest carbon footprint

Mailer Sizing Chart

If you've decided that mailers are right for your apparel business, this sizing chart is an excellent starting point. If you're unsure what size you need, we strongly recommend ordering free samples to ensure you choose your ideal size.

| Poly Mailers | Kraft Mailers | EcoX Mailers | Apparel Mailers | |

|

Sweater

|

12 x 15.5" or 14.5 x 19"

|

12.5 x 19"

|

10.5 x 4 x 19"

|

12 x 15" or 10.5 x 4 x 19"

|

|

T-Shirt

|

9 x 12"

|

6 x 2.5 x 12"

|

9 x 12"

|

10 x 13"

|

|

Dress Shirt

|

10 x 13"

|

6 x 2.5 x 12"

|

9 x 12"

|

10 x 13"

|

|

Two Shirts

|

10 x 13"

|

9.5 x 14.5"

|

10 x 13"

|

12 x 15"

|

|

Three Shirts

|

12 x 15.5"

|

12.5 x 19"

|

10 x 13"

|

10.5 x 4 x 19"

|

|

Dress

|

12 x 15.5" or 14.5 x 19"

|

12.5 x 19"

|

12 x 15.5"

|

12 x 15" or 10.5 x 4 x 19"

|

|

Socks or Baby Clothes

|

6 x 9"

|

6 x 2.5 x 12"

|

7 x 9"

|

7 x 9" or 10 x 13"

|

|

|

|

|

|

Inner Packaging Bags: Paper vs Plastic

The ubiquitous clear poly bag is an issue fashion brands are looking to tackle. Manufacturers package garments individually in clear plastic bags to keep them clean and separated as they travel to distribution facilities, retailers, or fulfillment centers. In fulfillment centers, these bags help receivers stock items properly, and pickers ensure they have pulled the correct goods for each order. This creates a lot of single-use plastic almost always made of virgin material. As a result, progressive brands actively seek alternatives, including eliminating these bags.

EcoEnclose offers four eco-friendly alternatives. Here we compare the Poly Bag, Glassine Bag, and Kraft Bag and not our fourth option - EcoBand Paper Product Wrap - because it is not an excellent solution to protect a product from factory to end consumer.

You can use this widget to input arbitrary HTML code into the page. Invalid HTML code may cause issues with the preview pane.

Kraft Bag & Seals

Our most circular inner packaging solution. Made with 100% recycled content and 60% post-consumer waste, are curbside recyclable paper, and close with a self-seal strip.

Available in 4 sizes

Ready to ship | Min. 25 units

Customizable | Min. 500 units

Kraft Bags

Our most circular inner packaging solution. Made with 100% recycled and 90% post-consumer waste, are curbside recyclable paper, and have an open top with no seal.

Available in 3 sizes

Ready to ship | Min. 25 units

Customizable | Min. 500 units

Poly Bags

Our lowest carbon footprint solution. Made with 100% recycled content, protects from moisture, thin-film recyclable, and available with and without suffocation warning.

Available in 7 sizes

Ready to ship | Min. 200 units

Customizable | Request a quote

Glassine Bags

Our translucent, curbside recyclable solution. The supercalendared paper is toothless and weather-resistant. Made from FSC® certified virgin paper with a resealable adhesive strip.

Available in 7 sizes

Ready to ship | Min. 25 units

Customizable | Min. 500 units

Comparing Our Eco-Friendly Inner Packaging Solutions

None of our inner packaging solutions are the perfect eco solution, and there are no clear eco winners. However, some products score best in certain categories. Here, we provide our reasoning.

Source Materials

Winner: 100% Recycled Kraft Bags

We prioritize packaging with as much recycled content as humanly possible, emphasizing post-consumer waste. Our Kraft Bags are made from 100% recycled natural Kraft paper. They come with or without a seal. Those without a seal are made with 90% post-consumer waste, and those with a seal are made with 60% post-consumer waste.

Our Glassine Bags are made from paper and FSC certified, utilizing wood from a controlled blend of trees in British Columbia, CA: Western Yellow; Red Cedar, and BC Interior Spruce, Pine; Fir (SPF). While FSC certified, they are made with virgin paper - making them less ecological than the Kraft Bag & Seals.

Our Poly Bags are made with 100% recycled post-industrial plastic. While post-industrial content is not as impactful to the planet as post-consumer content, we have been unable to achieve as clear of a bag as is needed when post-consumer content is added.

Carbon and Emissions of Manufacturing

Winner: 100% Recycled Poly Bags

The manufacturing process of a paper package is more carbon-intensive and polluting than that of an equivalently sized plastic package.

While this differential exists between our 100% recycled clear poly bags and our glassine and kraft bags, two factors make the difference between our Poly Bags and Glassine Bags particularly great.

The first is that glassine is entirely virgin. Secondly, glassine is more energy-intensive to produce than traditional paper. This is because the lignin must be completely removed from the raw wood chips (requiring more bleach and heat than standard paper) and because of the high heat and pressure necessary for super calendaring. Finally, our Poly Bags are 100% recycled, meaning their carbon footprint and emissions are lower than virgin poly film.

Carbon and Emissions of Transport

Winner: 100% Recycled Poly Bags

Glassine Bags are more than three times thicker and heavier than Poly Bags. Kraft Bags are even thicker than glassine bags! This means transporting and storing these paper alternatives takes three times the resources.

However, it is essential to note that for most manufactured goods, transportation represents 3-10% of the carbon footprint - not significant, but also not a major contributor.

End-of-Life

Winners: Glassine and Kraft Bags

This is where the Kraft and Glassine Bags truly shine! We prioritize materials that are easily recyclable as this is the best ecological option for a package (after reuse). These bags are paper, so they are easily recycled curbside with paper products. Additionally, they are naturally biodegradable and compostable. Although these bags are technically compostable, we don’t advocate for composting Glassine Bags or Kraft Bags.

Recycling is far more eco-friendly for paper packaging, especially the type of high-quality paper found in Glassine Bags. However, if they happened to end up as litter, they would biodegrade in natural environments. 100% Recycled Poly Bags are recyclable but not biodegradable.

Like all thin film, they cannot be curbside recycled as the flimsy material gets caught in the gears of the sorting equipment at materials recovery facilities. They must be recycled at thin-film drop-offs, found in almost every grocery store and big-box retailer nationwide. Because of this inconvenience, they have lower recycling rates than paper (

11.5% for plastic bags compared to 66% for paper goods).

Functionality

Winner: 100% Recycled Poly Bags

It is hard to beat the functionality of any plastic, including 100% Recycled Poly Bags - fully waterproof, clear, and durable. Clear poly bags protect goods and allow for easier sorting and storage by their retailers. They are also often a packaging requirement set by third-party fulfillment centers such as Amazon FBA.

Runner Up: Glassine Bags

We are thrilled about Glassine Bags because they offer a lot of the functionality companies need for this wholesale packaging. They are translucent enough to see an item's color and scan its barcode. These bags also offer some moisture resistance. Unlike standard paper, glassine is toothless and doesn’t irritate goods or run paper fibers onto contents. Glassine also does not produce static, unlike poly film. Additionally, we love that our Glassine Bags are gusseted and have air holes, making them easy to use in a high-speed operation.

Cost

Winner: 100% Recycled Poly Bags

Paper is more expensive than plastic; this cost differential can be seen in our pricing for Poly Bags and Glassine Bags. Depending on your desired size and quantity, Glassine Bags are 2.5 to 4 times the price of Poly Bags.

Branding and Aesthetics

Winners: Kraft and Glassine Bags

We love the aesthetics of the Kraft Bags. They have a natural look and can be custom branded in relatively low quantities. Because this is internal packaging rather than an outer shipping solution, the likelihood that a well-branded Kraft Bag ends up in customers' hands without blemishes or scuffs is high. Additionally, whether branded or not, Kraft Bags are not a very common internal packaging solution, especially our Kraft Bag & Seals. Customers will notice that your packaging strategy is unique in its effort to be more sustainable.

We also know that many brands love the unique appearance of glassine bags. They are translucent and have a unique, soft, smooth finish. They can also be beautifully custom branded at order quantities of just 500.

Additional Information

For more information on the Fashion Industries quest for a more sustainable poly bag, and a comparison of eco features of different options, check out this paper by Fashion For Goods. The graphic on page 29 of the report is particularly effective at summarizing some key trends when comparing various poly bag options and alternatives.

Sustainable Packaging Inspiration

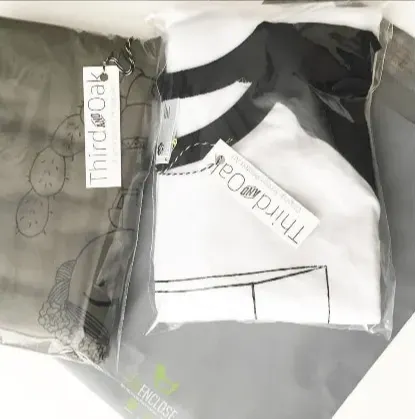

Twelve Bees protects their cloths in 100% Recycled Poly Bags and packages them in 100% Recycled Poly Mailers.

Cotton Squad packages their shirts in a 100% Recycled Custom Shipping Box with tissue paper for protection and presentation.

Third and Oak protects their clothes in 100% Recycled Poly Bags and packages them in 100% Recycled Poly Mailers.

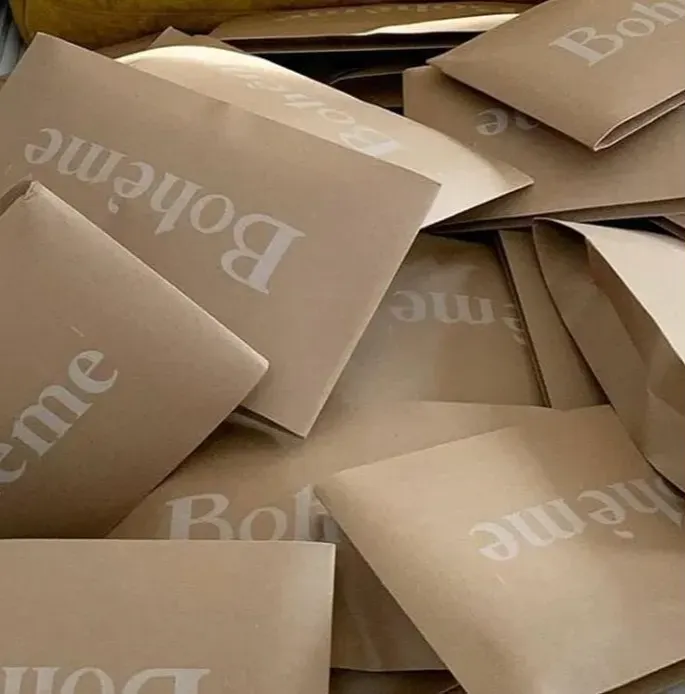

Boheme uses our largest, gusseted size of 100% Recycled Paper Apparel Mailers to ship vintage clothing.

Looking for Guidance?

We'd love to help you find the right shipping solution for your business.