Resources

By Focus Area

By Resource Type

Sort By :

No Results

-

The World's Most Sustainable Ink

-

Custom Packaging Inspiration

-

Shop Packaging By Industry

-

Packaging for Apparel

-

Packaging for Cosmetics

-

Packaging for Jewelry

-

Packaging for Retail

-

Packaging for Essential Oils, CBD Oils, and Other Tinctures

-

Packaging for Soap

-

Packaging for Artwork

-

Packaging for Bags, Backpacks and Purses

-

Packaging for Subscription Boxes

-

Packaging for Food

-

Packaging for Marketing

-

Six Steps to Plastic-Free Packaging

-

Transitioning From Plastic To Paper Packaging

-

Shop Plastic-Free Packaging

-

Plastic-Free Stickers and Labels

-

Finding an Alternative to Poly Mailers

-

Finding an Alternative to Clear Poly Bags

-

Finding an Alternative to Bubble Wrap

-

Why A Virgin Packaging Strategy Falls Short

-

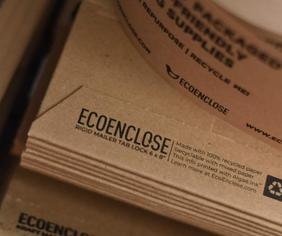

Which Paper Mailer Is Right For Your Business?

-

The Best Paper Mailers for Apparel

-

Our Bioplastics Research Hub

-

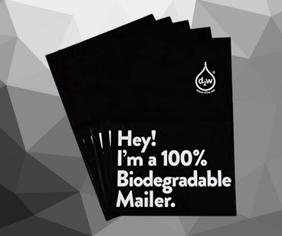

Bioplastics and Dissolvable Plastics for eCommerce Packaging

-

Bioplastic is Not Plastic Free

-

Paper versus Plastic (and Bioplastic)

-

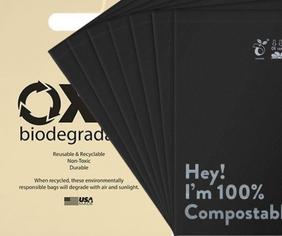

We Could Sell This Biodegradable Poly Mailer (We Won't)

-

How to Recycle or Reuse Your Packaging

-

Our Curbside Recyclable Packaging Solutions

-

Recycling Vs Composting: What's The Difference?

-

Looking for Compostable Packaging? Read This First.

-

Our Plastic Film Take-Back Program

-

Glossary of Sustainable Packaging Terms

-

Shop By Sustainability Features

-

What’s The ROI Of Sustainable Packaging?

-

How to Design Packaging for Recyclability

-

Why Recycled Content Matters

-

Compostable Mailers: Finding The Best Option

-

What Can I Do About Marine Plastic Pollution?

-

Guide to Sustainable Certifications

-

Responsible Packaging Movement

-

Canopy Pack4Good

-

Downloadable Lunch & Learns to Train Your Team

-

Guide to Sustainable Packaging Requirements and Legislation

-

Calculate Your Sustainability Savings

-

Paper Packaging Eco Savings Calculator

-

Shipping Box Eco Savings Calculator

-

Eco Savings Calculator: Reusable Mailers

-

Ultimate Guide to Shipping Boxes

-

Ultimate Guide to Poly Mailers

-

Definitive Guide to eCommerce Packaging

-

Definitive Guide to Protective Packaging & Void Fill

-

Definitive Guide to Custom Stickers

-

Definitive Guide to Reusable Packaging for Ecommerce

-

Ultimate Guide to Padded and Bubble Mailers

-

How To Fold A Tab Locking & Literature Mailer Box

-

Printer Compatibility With Our Direct Thermal Labels

-

Video Packaging Tutorials

-

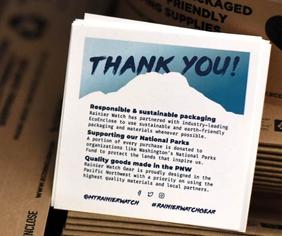

Tell Your Brand's Sustainable Packaging Story

-

Digital Assets By Product

-

Artwork Guidelines

-

Custom Shipping Box Artwork Guidelines

-

Custom Mailer Artwork Guidelines

-

Custom Glassine Bag Artwork Guidelines

-

Custom Kraft Bag Artwork Guidelines

-

Custom Paper Shopping Bag Artwork Guidelines

-

Custom Tissue Paper Artwork Guidelines

-

Custom Sticker Artwork Guidelines

-

Custom Packing Tape Artwork Guidelines

-

Custom Card Artwork Guidelines

-

Custom EcoBand Artwork Guidelines

-

Sustainable Packaging Case Studies

-

Case Study | Tombolo

-

Case Study | American Dairy Association NE

-

Case Study | Bedrock Sandals

-

Case Study | Armoire

-

Case Study | Scentbird

-

Case Study | Fjallraven

-

Case Study | Rocky Mountain Oils

-

Enterprise Custom Packaging

-

Enterprise Capabilities

-

Our Sustainability Vision

-

Our Sustainable Packaging Framework

-

Our Packaging Innovations

-

Our Collective EcoImpact

-

Guide to Fabric Sustainability

-

Eco-Friendly Supplier Guide For E-Commerce Businesses

-

Case Study | The Gentle Pit

-

Poly Packaging Eco Savings Calculator

-

Guide to Retailer Packaging and Sustainability Requirements

-

Walmart's Packaging and Sustainability Requirements

-

Ulta Beauty's Packaging and Sustainability Requirements

-

Sephora's Packaging and Sustainability Requirements

-

Amazon’s Frustration-Free Packaging Program

-

Costco's Packaging and Sustainability Requirements

-

Whole Foods' Packaging and Sustainability Requirements

-

Kroger's Packaging and Sustainability Requirements

-

DICK'S Sporting Goods Packaging and Sustainability Requirements

-

CVS'Packaging and Sustainability Requirements

-

Target's Packaging and Sustainability Requirements

-

Guide to Thin Film Recycling and How2Recycle® Labeling

-

EcoEnclose & Certifications

-

Guide to Packaging Compliance

-

Seaweed as a Packaging Input

-

Packaging Made From Seaweed

-

Custom Jewelry Box Artwork Guidelines

-

Environmental Paper Network: Paper Calculator

-

AF & PA: Design Guidance for Recyclability

-

Canopy Planet: Canopy: LCA Guidance

-

Sustainable Packaging Coalition: Centralized Study on Availability of Recycling

-

Canopy Planet: NextGeneration Benefits Brief

-

Ellen MacArthur Foundation: Upstream Innovation

-

Accelerating Circularity: Directory of Textile to Textile Recyclers

-

Canopy Planet: EcoPaper Database

-

Pathway for Circularity for Packaging: Circular Packaging Assessment Tool

-

Our Stance on PVC

-

Reverse Logistics, Returns and Recommerce

-

There is No Such Thing as Sustainable Packaging (Yet)

-

A Look Back at 2022: Reflections and Lessons Learned

-

10 Steps to Develop Your 2024 Sustainability Plan

-

CanopyStyle Summit 2022: Reflections and Insight

-

How to Choose the Best Custom Mailers for Your Brand

-

Shop Your Values This Holiday Season

-

What is Greenwashing? How to Spot It and Avoid It.

-

The Ultimate Guide to Recycling During the Holidays in 2023

-

Sustainable Alternatives to Clear Poly Bags

-

Unsustainable Holiday Packaging Solutions to Avoid

-

Climate Wins That Inspire Action

-

The Case Against Degradable Plastic Packaging

-

The Ultimate List of Eco-Friendly & Environmental Holidays [A Guide to Green Holidays]

-

2022 Holiday Planning Tool

-

How to Plan for The 2022 Holiday Season

-

Choosing the Most Sustainable Retail Boxes

-

A Half Year In Review: Reflections and Lessons Learned From 2022 (So Far)

-

Unboxing Strategies in 2023: Marketing for Modern Consumers

-

Tree Planting Initiatives: The Good, the Bad and the Ugly

-

Plastic Free July 2022: A Step-By-Step Guide

-

How Algae Printer Ink Is Changing the Industry

-

Prioritizing Sustainability in a Recession is Good for Business and the Planet

-

Direct-to-Consumer (D2C): What It Means, Challenges, And More

-

Ten Sustainability Myths Busted

-

Are Custom Poly Mailers Right For My Brand?

-

Recycled Content Versus Bioplastics

-

The Psychology of Custom Tissue Paper

-

Finding the Most Sustainable Custom Stickers for Your Brand

-

Here’s What to do With Those Annoying Produce Stickers

-

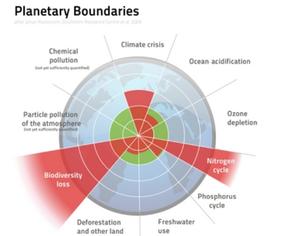

Why We Need to Talk About Biodiversity and Packaging

-

What is Glassine?

-

Eco-Friendly Adhesives In the World of Sustainable Packaging

-

Sourcing The Most Sustainable Paper

-

Why Recycled Content Matters Now More Than Ever

-

Buy Recycled Across Your Business: Ideas and Resources

-

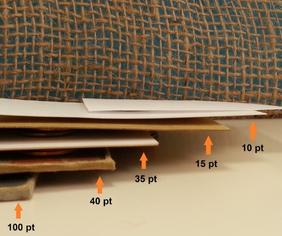

Understanding Shipping Box Strength

-

Points, Pounds, GSM: What Do You Need in Paper Packaging?

-

Earth Day 2022: Invest in Our Planet

-

Choosing Between Reusable Mailers and Poly Mailers

-

Find The Most Eco-Friendly Packing Tape (in 2022)

-

This Common Packaging is a Recycling Nightmare

-

How to Package Fragile Items for Shipping (in 2022)

-

Why We Prioritize Domestic Manufacturing

-

Tissue Paper: To Recycle or Compost?

-

Introducing Sustainable Business Cards and Hang Tags

-

What is the Most Sustainable Ink? (In 2022)

-

When To Consider Reusable Packaging for Ecommerce (in 2022)

-

10 Steps to Finding Your Perfect Sustainable Packaging

-

Custom Packaging: Is it Worth it to Ship in Style?

-

Moving Your Fulfillment Center to a Sustainable Packaging Strategy

-

Suffocation Warnings: Legal Packaging Requirements in 2023

-

A Look Back at 2021: Reflections and Lessons Learned

-

USPS Services and Packaging Requirements in 2023

-

The Collective Impact of Our EcoAlly Community in 2021 (So Far!)

-

The Glasgow Climate Pact 2021

-

Are Next-Generation Fibers The Future of Sustainable Paper?

-

Extended Producer Responsibility, The Planet, and Your Business

-

Eco-Friendly Protective Packaging Options

-

GreenWrap Dispensers: Refillable versus Disposable

-

The Impact of Pigments, Adhesives and Release Liners

-

Minimize Shipping Damage in Your Ecommerce Deliveries

-

Right-Size Your Sustainable Packaging

-

Packaging Life Cycle Analysis: What it Tells Us, What It Doesn’t

-

Should I Use White or Kraft for Custom Shipping Boxes?

-

Ten Lessons From the Sustainability Goals of Leading Brands

-

Beyond the Box: Best Eco-Friendly Shipping & Packaging Accessories

-

Plastic Free Is Just the Beginning, Seek Out Sustainable Natural Fibers

-

Aluminum versus Glass versus Plastic: What Single Use Packaging Option is Best

-

Nine Recycling Myths Busted

-

What to Look for in Eco-Friendly Packaging & Supplies

-

What’s the Difference Between Recyclable and Compostable Packaging?

-

Paper vs. Plastic: Which Should I Use for My Packaging?

-

Custom Notecards Can Tell Your Packaging Story

-

Using QR Codes to Tell Your Sustainable Packaging Story

-

Takeaways from SPC Impact 2021 and the Sustainable Packaging Coalition

-

Minimum Order Quantities: What They Are and Why We Have Them

-

The Most Important Question to Ask when Seeking Sustainable Packaging

-

Restore Our Planet: Yes, It Is Possible

-

Post Consumer vs Post Industrial Recycled Content

-

Custom Packaging: Inline Printing Inspiration

-

How to Choose Between a Mailer and a Shipping Box

-

Why Landfill Diversion Is So Important

-

Carbon Neutral Shipping

-

Nine Planetary Boundaries

-

Don't Replace Fossil Fuels with Corn: Lessons from Ethanol

-

Compostable Does Not Mean Naturally Biodegradable

-

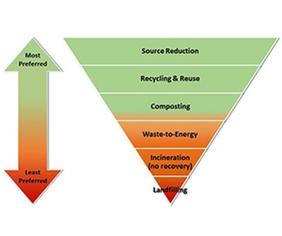

A Hierarchy of Waste Reduction and Diversion

-

Composters Don't Want Your Packaging, Especially Your Bioplastic